PRODUCTS

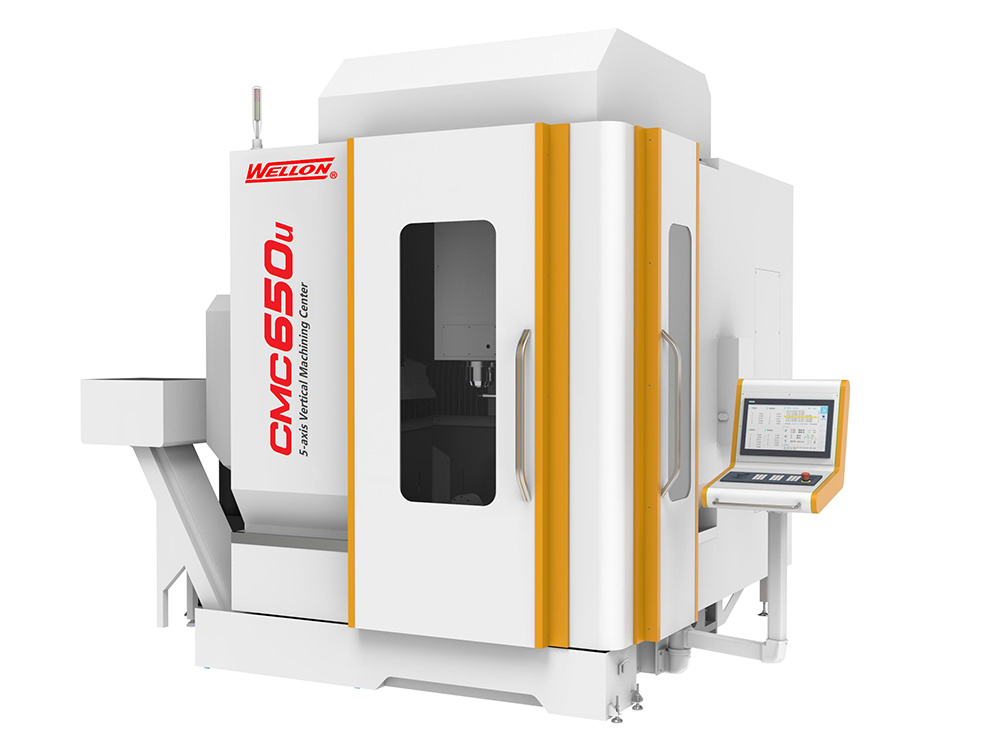

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.