PRODUCTS

1.The working table of the machine tool is provided with three different directions of feed (longitudinal, horizontal and rotary), therefore work object go through once clamping, Several surfaces in the machine tool machining 2.Hydraulic transmission mechanism with sliding pillow reciprocating motion and hydraulic feed device for working table. 3.The sliding pillow has the same speed in every stroke, and the movement speed of the ram and the working table can be adjusted continuously. 4.Hydraulic control table have ram commutation oil for oil reversing mechanism, In addition to hydraulic and manual feed outer, Even there single motor drive vertical, horizontal and rotary fast moving. 5.Use hydraulic feed the slotting machine, Is when the work is over turning back instantaneous feed, Therefore be better than mechanical slotting machine used drum wheel feed.

1.The working table of the machine tool is provided with three different directions of feed (longitudinal, horizontal and rotary), therefore work object go through once clamping, Several surfaces in the machine tool machining 2.Hydraulic transmission mechanism with sliding pillow reciprocating motion and hydraulic feed device for working table. 3.The sliding pillow has the same speed in every stroke, and the movement speed of the ram and the working table can be adjusted continuously. 4.Hydraulic control table have ram commutation oil for oil reversing mechanism, In addition to hydraulic and manual feed outer, Even there single motor drive vertical, horizontal and rotary fast moving. 5.Use hydraulic feed the slotting machine, Is when the work is over turning back instantaneous feed, Therefore be better than mechanical slotting machine used drum wheel feed.

1.The working table of the machine tool is provided with three different directions of feed (longitudinal, horizontal and rotary), therefore work object go through once clamping, Several surfaces in the machine tool machining 2.Hydraulic transmission mechanism with sliding pillow reciprocating motion and hydraulic feed device for working table. 3.The sliding pillow has the same speed in every stroke, and the movement speed of the ram and the working table can be adjusted continuously. 4.Hydraulic control table have ram commutation oil for oil reversing mechanism, In addition to hydraulic and manual feed outer, Even there single motor drive vertical, horizontal and rotary fast moving. 5.Use hydraulic feed the slotting machine, Is when the work is over turning back instantaneous feed, Therefore be better than mechanical slotting machine used drum wheel feed.

1. This machine is used for slotting the flat and formed surface key ways, etc. 2. It is suitable for either single piece of small batch production 3. The main transmission mechanism is used for converting the rotating motion of the crank gear into reciprocating motion of rain 4. The worktable Is designed for longitudinal, cross and rotary feeding both automatically (only for D type model) and manually 5. The feed is stopped automatically, when the worktable is in case of trouble

1. This vertical slotting machine is suitable for vertical planning active surfaces and grooves of parts etc. 2. The machine runs smoothly owing to it adopts double crank mechanism. 3. It operates easily because the worktable motion is driven by PLC System and Rotary Feeds of Servo Motor System. 4. The working table can make rotary positioning mechanically, which is convenient for planning multi keyway. It can feed stepless continuously, and also the feeding parameter is displayed in the indicator. 5. The mechanical system is turning for long time, the control system make the error compensation and ensure the processing precision.

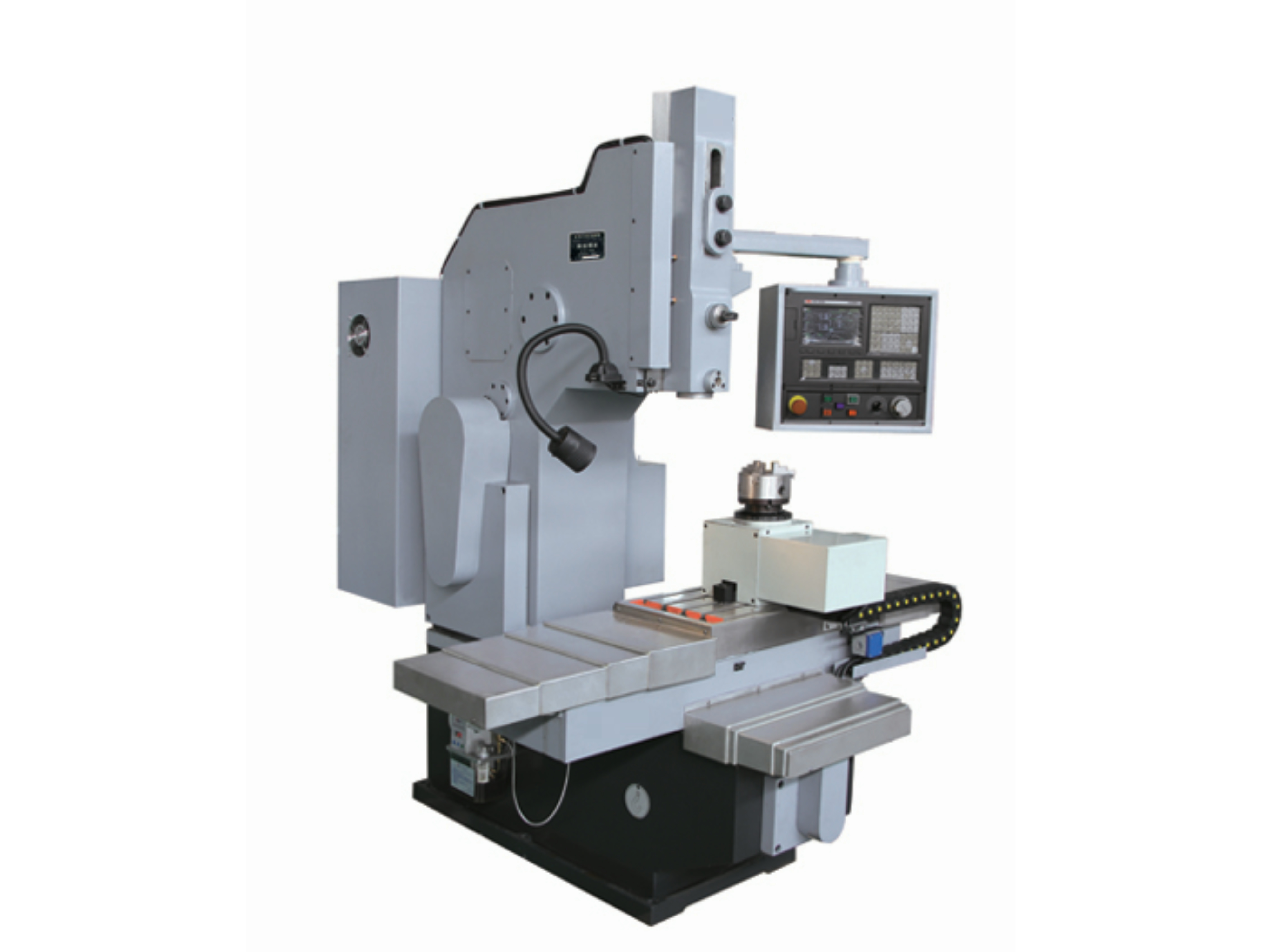

1. This CNC slotting machine mainly adopts GSK980MDC CNC system, and the worktable only make movements on Y axis. 2. This ram dovetail is modified to linear guide-way. 3. Y axial guide rail is restructured to linear guide-way. 4. The CNC system could control cutting speed, and main motor adopts servo motor. 5. Y axial lead screw mainly adopts prepressing by double nuts. 6. Verticality of Z axis & Y axis ≤0.025mm. 7. Y linear encoder (Sino) Amplifier Display. 8. Reserve swivel table communication interface

BK5030 CNC slotting machine is a new product designed and developed by our company,This machine has a slotting plane, forming surface and keyway function. It is a slotting machine that realizes slotting by digital control.The main drive adopts the crank handle mechanism, and the servo motor realizes the large torque transmission through the deceleration. The X and Y feeds the servo control to realize the stepless speed regulation function, the X direction ball screw and the motor are directly connected, and the Y direction ball screw and the The motor is transferred through the timing belt. According to the user's needs, the CNC indexing head or CNC rotary disc can be configured. The machine tool is powerful and can process keyways in different angle directions.The machine has high power, good rigidity, large precision reserve, high cost performance, long service life, and can be widely used in machine tools and automobile manufacturing, various mechanical and electrical and aerospace industries. It is an ideal equipment for keyway processing of various materials.