PRODUCTS

It can automatically process the inside and outside cylinder surface, cone surface, circle arc surface,end face. It can also turn the single and multiple threads in metric , inch and other standard. 1.High rigidity pedestal and wider lay board are suitable for heavy cutting 2.Four station electric turret 3.Frequency conversion stepless speed regulation

It can automatically process the inside and outside cylinder surface, cone surface, circle arc surface,end face. It can also turn the single and multiple threads in metric , inch and other standard. 1.High rigidity pedestal and wider lay board are suitable for heavy cutting 2.Four station electric turret 3.Frequency conversion stepless speed regulation

It can automatically process the inside and outside cylinder surface, cone surface, circle arc surface,end face. It can also turn the single and multiple threads in metric , inch and other standard. 1.High rigidity pedestal and wider lay board are suitable for heavy cutting 2.Four station electric turret 3.Frequency conversion stepless speed regulation

It can automatically process the inside and outside cylinder surface, cone surface, circle arc surface,end face. It can also turn the single and multiple threads in metric , inch and other standard. 1.High rigidity pedestal and wider lay board are suitable for heavy cutting 2.Four station electric turret 3.Frequency conversion stepless speed regulation

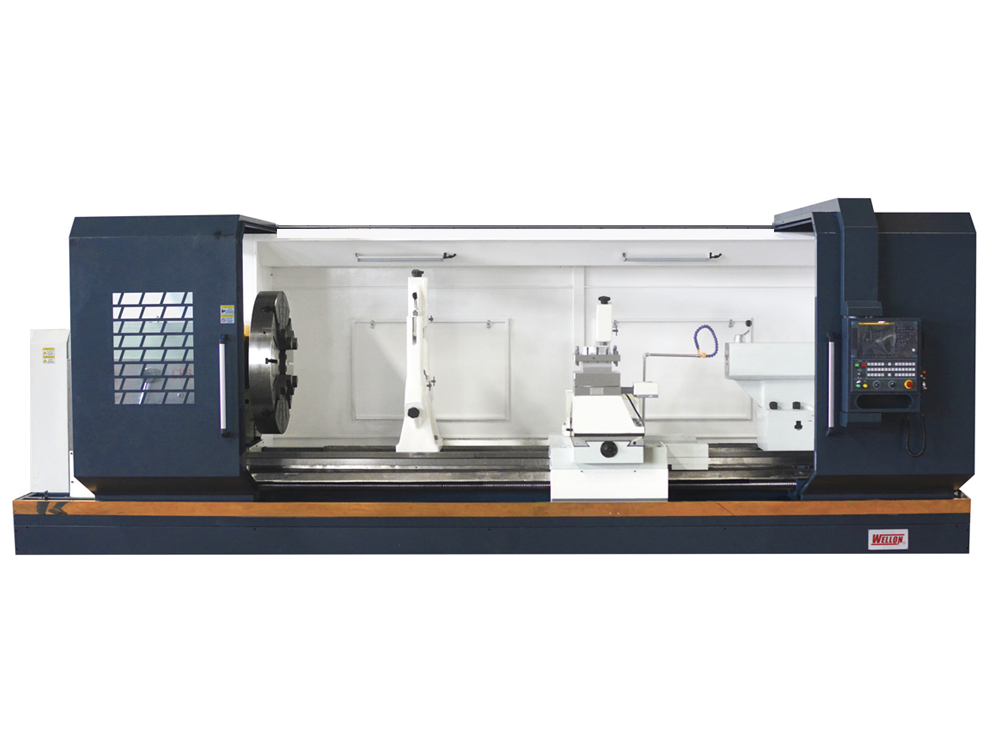

This machine tools is a mature product has a compact structure, beautiful appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent accuracy retention.This series machine can automatically process the inside and outside cylinder surface, cone surface, circular arc surface, end face, such as processing, and also can process the single and multiple threads in metric, inch and other standards.

CK Series are economical and practical CNC lathes.With optimized structures, unfailing performance, high quality, simple programming, and easy handling, they are suitable for turning of complicated shaft, sleeve, and disk type work-pieces such as turning of internal and external cylindrical, conical, arc surfaces and various threads, and even drilling, boring and reaming holes. And they are especially fit for turning of diversified work-pieces on small and medium batches. They are of high versatility high efficiency, low inferiority and good comfort ability. So to be widely used in various trades, such as automobile industry. Petroleum industry, military industry, and so on.

CK Series are economical and practical CNC lathes.With optimized structures, unfailing performance, high quality, simple programming, and easy handling, they are suitable for turning of complicated shaft, sleeve, and disk type work-pieces such as turning of internal and external cylindrical, conical, arc surfaces and various threads, and even drilling, boring and reaming holes. And they are especially fit for turning of diversified work-pieces on small and medium batches. They are of high versatility high efficiency, low inferiority and good comfort ability. So to be widely used in various trades, such as automobile industry. Petroleum industry, military industry, and so on.

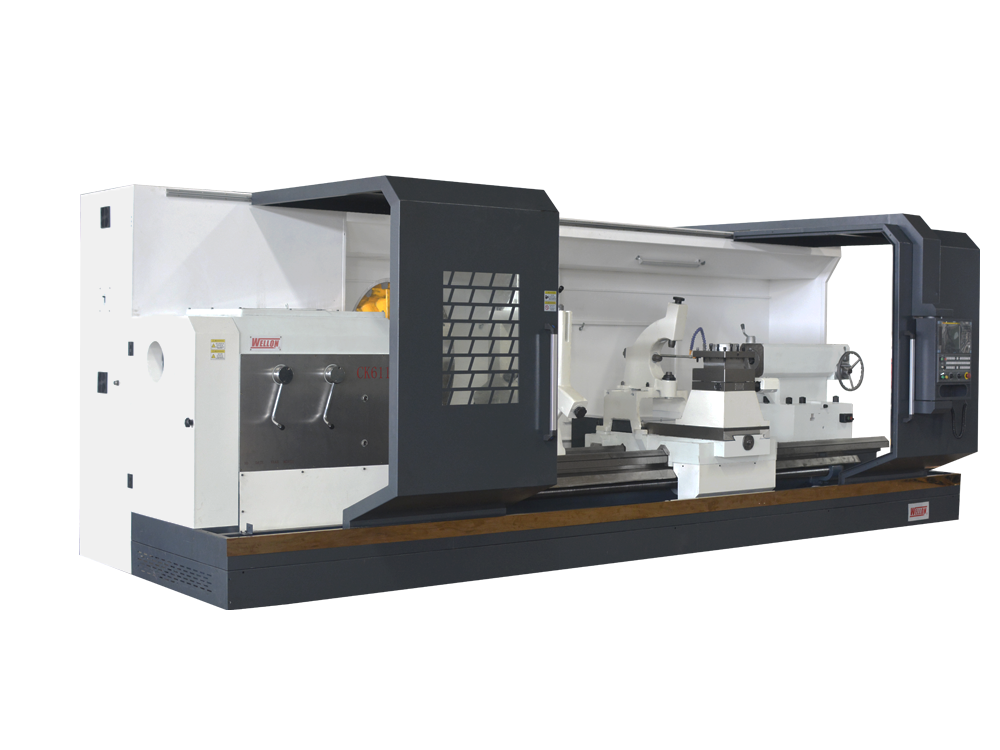

This lathe are suitable for turning internal and external cylindrical, conical and swing surfaces as well as various metric, inch, module and diametric pitch threads.They can also be used for broaching oil grooves and keyways. There are also following features: 1. Box type internal structure, of high rigidity , with hardened guideway. The precision is stable.And can carry out strong force cutting. 2. On apron,there is a device, operated by a single lever, used for rapid traverse of the carriage. 3. The saddle guideway is glued by ‘TSF’ soft belt wear resisting materials. 4. The top slide can be used independently for turning of short cone, in combination with longitudinal feeding, it can also turn long taper surface.

This lathe are suitable for turning internal and external cylindrical, conical and swing surfaces as well as various metric, inch, module and diametric pitch threads.They can also be used for broaching oil grooves and keyways. There are also following features: 1. Box type internal structure, of high rigidity , with hardened guideway. The precision is stable.And can carry out strong force cutting. 2. On apron,there is a device, operated by a single lever, used for rapid traverse of the carriage. 3. The saddle guideway is glued by ‘TSF’ soft belt wear resisting materials. 4. The top slide can be used independently for turning of short cone, in combination with longitudinal feeding, it can also turn long taper surface.

1.Independent spindle , high precision ,lower noise , saving energy and protect environment 2. High speed and precision bearing, spindle smooth finish good. High precision ball screw 3.High stability one- piece machine bed, higher rigidity cast iron. 4.High frequency quenching rail, hardness and high wear resistance. Frequency conversion, stepless speed regulation. Integrated automatic lubrication

1.Independent spindle , high precision ,lower noise , saving energy and protect environment 2. High speed and precision bearing, spindle smooth finish good. High precision ball screw 3.High stability one- piece machine bed, higher rigidity cast iron. 4.High frequency quenching rail, hardness and high wear resistance. Frequency conversion, stepless speed regulation. Integrated automatic lubrication