PRODUCTS

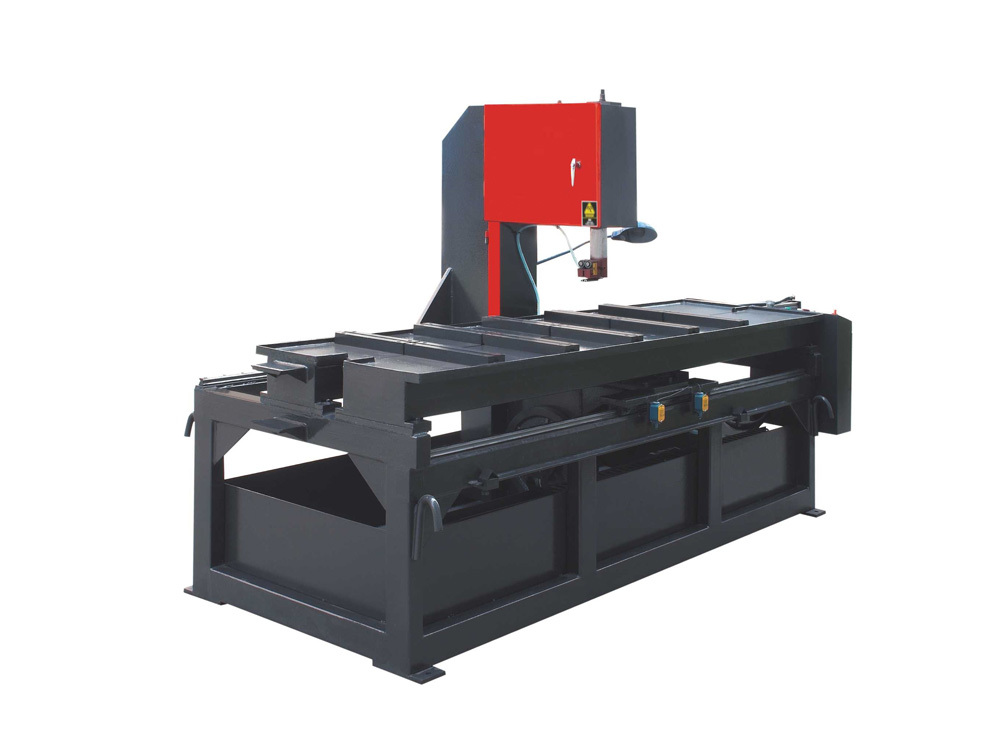

Can make various kinds of cutting such as beveling,shaping ,contour,slicing etc. Work table can be swiveled Blade can be welded easily and reused With variable speed can make various material cutting such as metal ,plastic wood rubber

Can make various kinds of cutting such as beveling,shaping ,contour,slicing etc. Work table can be swiveled Blade can be welded easily and reused With variable speed can make various material cutting such as metal ,plastic wood rubber

Can make various kinds of cutting such as beveling,shaping ,contour,slicing etc. Work table can be swiveled Blade can be welded easily and reused With variable speed can make various material cutting such as metal ,plastic wood rubber

Can make various kinds of cutting such as beveling,shaping ,contour,slicing etc. Work table can be swiveled Blade can be welded easily and reused With variable speed can make various material cutting such as metal ,plastic wood rubber

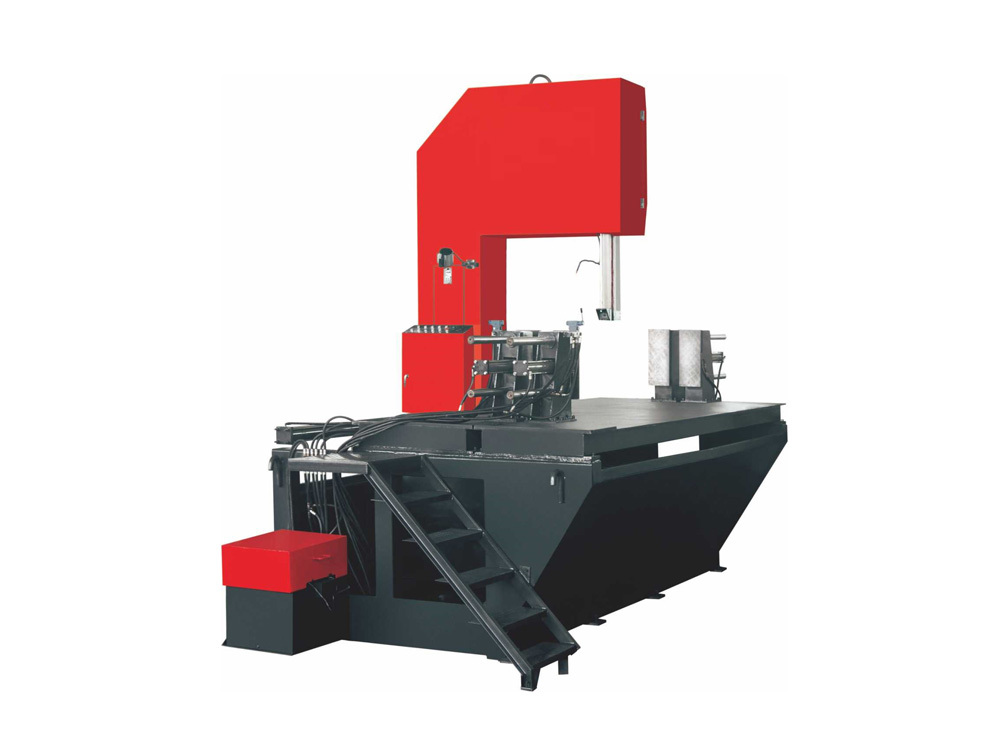

The sawing is controlled by hydraulic device. Reasonable design of working table is convenient for saw blade change.

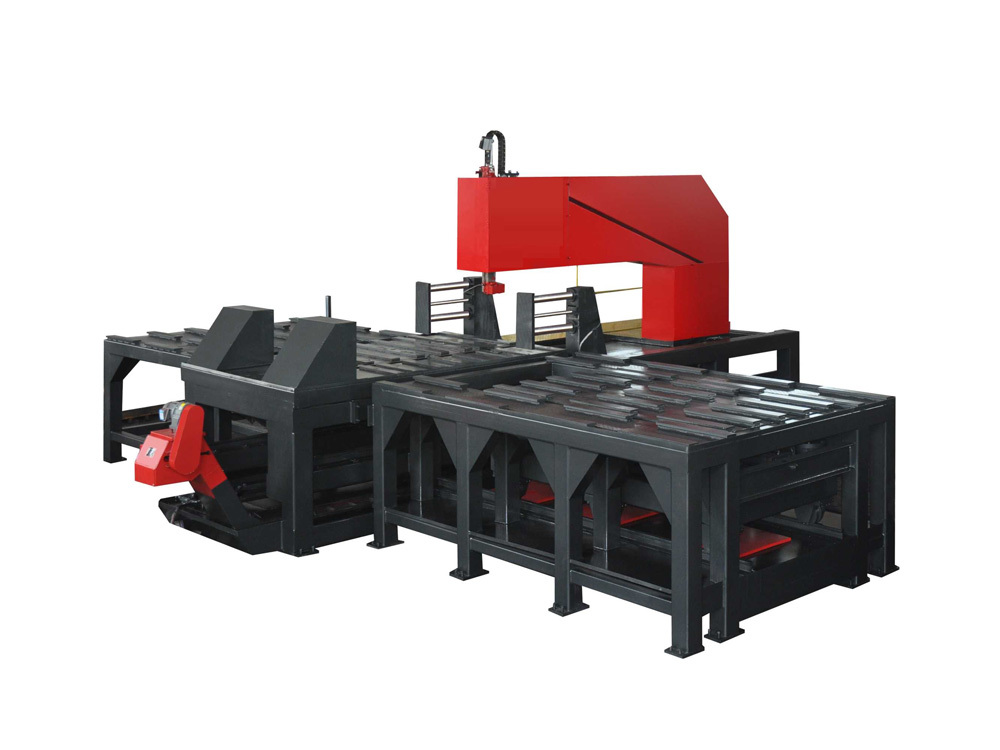

Feeding guiding adopts double-linear guiding rail, with high guiding precision small friction coefficient and long service life. The sawing is controlled by hydraulic device. Reasonable design of working table is convenient for saw blade change.

Cutter position adopt infrared system. The saw frame feeding adopts mechnical pulley automatic feeding system. The material feeding forward and backwards adopts the flate pully hydraulic system with high precision. Hydraulic lifting device matches the feeding strcuture. The saw blade tensioning is hydraulic, not easy to wear. We can develop automatic chip system band saw as customer’s requirements.

Feeding guiding adopts double-linear guiding rail, with high guiding precision small friction coefficient and long service life. The sawing is controlled by hydraulic device. Reasonable design of working table is convenient for saw blade change.

Cutter position adopts infrared system. The saw frame feeding adopts mechanical pulley automatic feeding system. The material feeding forward and backwards adopts the flat pulley hydraulic system with high precision. Hydraulic lifting device matches the feeding structure. The saw blade tension is hydraulic, not easy to wear. We can develop band saw automatic chip system as customer’s requirements.