PRODUCTS

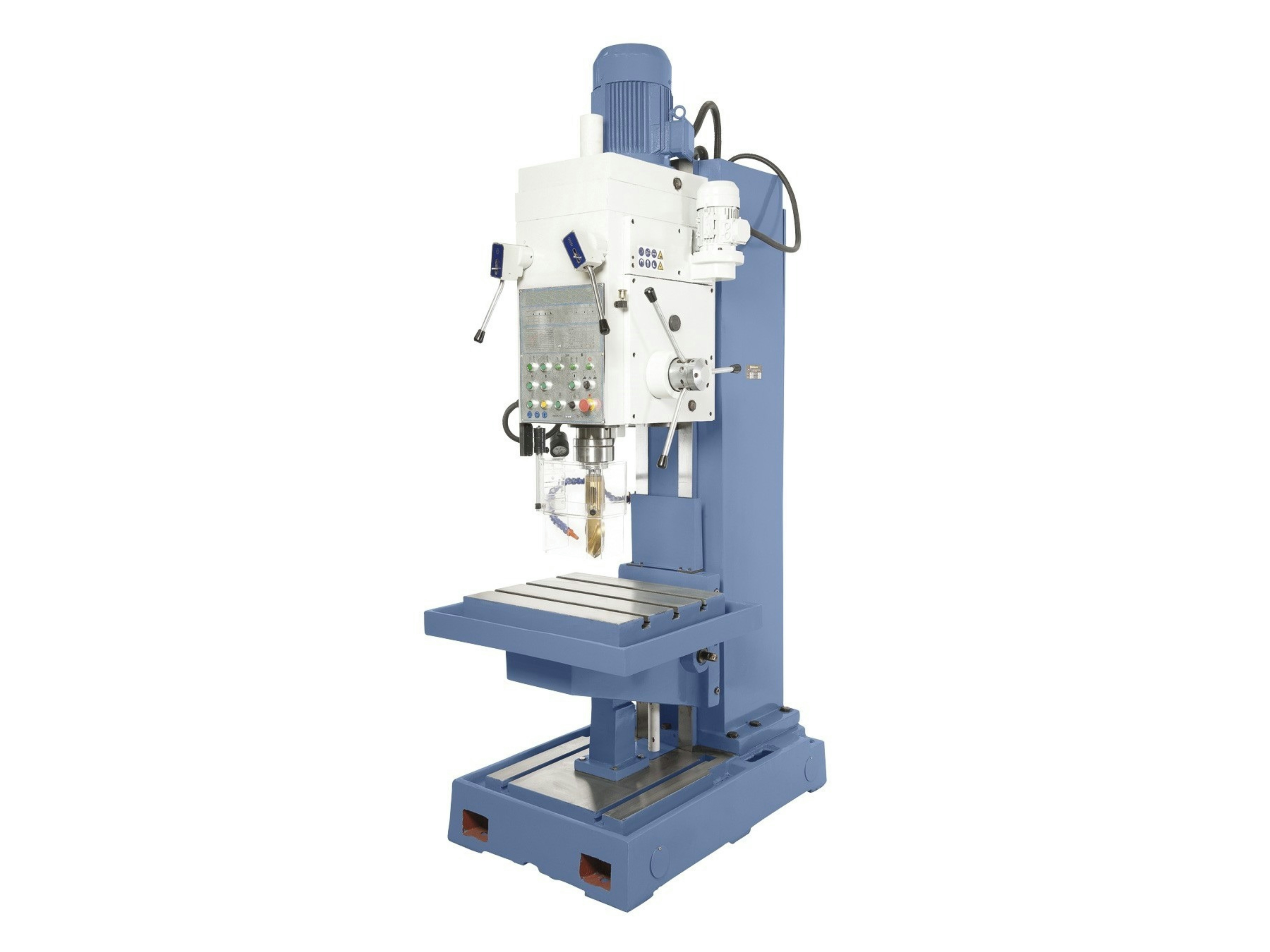

Quick and easy feed and speed control thanks to comfortable control lever Powerful motor of high torque as well as high pressure force and feed Threading at automatic rotations change and depth adaptation Automatic spindle feed in standard version, threading option and lighting Quick feed and return motor Trouble-free operation and long operation warranted by use of high class parts and components Column and base strong and solid structure

Quick and easy feed and speed control thanks to comfortable control lever Powerful motor of high torque as well as high pressure force and feed Threading at automatic rotations change and depth adaptation Automatic spindle feed in standard version, threading option and lighting Quick feed and return motor Trouble-free operation and long operation warranted by use of high class parts and components Column and base strong and solid structure

Quick and easy feed and speed control thanks to comfortable control lever Powerful motor of high torque as well as high pressure force and feed Threading at automatic rotations change and depth adaptation Automatic spindle feed in standard version, threading option and lighting Quick feed and return motor Trouble-free operation and long operation warranted by use of high class parts and components Column and base strong and solid structure

8 speed steps with positive torque transmission - no belt slippage Easy rpm adjustment via two shift levers and 2-step main motor Heavy construction with thick-walled column Hand wheel for vertical feed of head with solid dual-clamp Height adjustable table and head allow the user to set the optimal work height Work table swivels +/- 45 degree

8 speed steps with positive torque transmission - no belt slippage Easy rpm adjustment via two shift levers and 2-step main motor Heavy construction with thick-walled column Hand wheel for vertical feed of head with solid dual-clamp Height adjustable table and head allow the user to set the optimal work height Work table swivels +/- 45 degree

The machine is designed with multi-function of drilling. Broaching, reaming, tapping and facing milling. With a strengthened capacity of drilling it allows the workpieces to be drilled with larger range of size. It is suitable for using in both production and maintenance shops 1. Easy operation. 2. Casting iron structure for long durability. 3. Column type of vertical drilling machine. 4. Worktable can rotate 180 degree and tilt 45 degree 5.Worktable lifting by hand

Drilling,tapping,boring,reaming Strong column,Vice table,Gear drive,lower noise Heavy-duty tapered roller bearing spindle,Positive spindle lock

The machine is designed with multi-function of drilling. Broaching, reaming, tapping and facing milling. With a strengthened capacity of drilling it allows the workpieces to be drilled with larger range of size. It is suitable for using in both production and maintenance shops 1. Easy operation. 2. Casting iron structure for long durability. 3. Column type of vertical drilling machine. 4. Worktable can rotate 180 degree and tilt 45 degree 5.Worktable lifting both manual and motorized.

Specifications: The machine is designed with multi-function of drilling. Broaching, reaming, tapping and facing milling. With a strengthened capacity of drilling it allows the workpieces to be drilled with larger range of size. It is suitable for using in both production and maintenance shops 1. Easy operation. 2. Casting iron structure for long durability. 3. Column type of vertical drilling machine. 4. Worktable can rotate 180 degree and tilt 45 degree 5.Worktable lifting both manual and motorized.

The machine is designed with multi-function of drilling. Broaching, reaming, tapping and facing milling. With a strengthened capacity of drilling it allows the workpieces to be drilled with larger range of size. It is suitable for using in both production and maintenance shops 1. Easy operation. 2. Casting iron structure for long durability. 3. Column type of vertical drilling machine. 4. Worktable can rotate 180 degree and tilt 45 degree 5.Worktable lifting both manual and motorized.

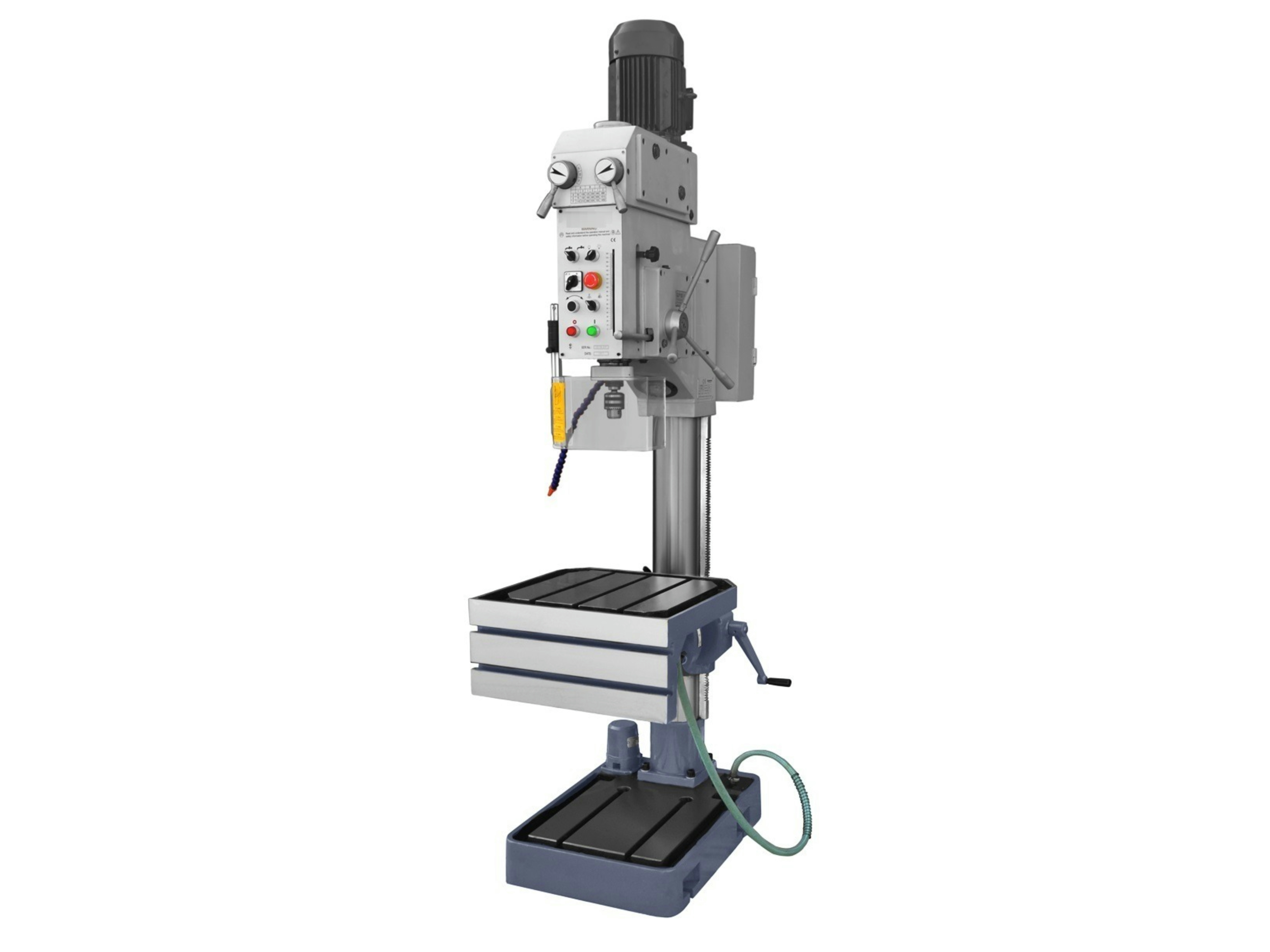

2 speed strong power motor, 18 steps speed which can improve the machining accuracy and producing efficiency. 2 steps power feed 0.1-0.2mm/rev Drilling, tapping, boring, reaming; Automatic tools ejectors Strong column, table can rotary and tilting, Gear drive, lower noise;

2 speed strong power motor, 18 steps speed which can improve the machining accuracy and producing efficiency. 2 steps power feed 0.1-0.2mm/rev Drilling, tapping, boring, reaming; Automatic tools ejectors Strong column, table can rotary and tilting, Gear drive, lower noise;

2 speed strong power motor, 18 steps speed which can improve the machining accuracy and producing efficiency. 2 steps power feed 0.1-0.2mm/rev Drilling, tapping, boring, reaming; Automatic tools ejectors Strong column, table can rotary and tilting, Gear drive, lower noise;

The machine is designed with multi-function of drilling. Broaching, reaming, tapping and facing milling. With a strengthened capacity of drilling it allows the workpieces to be drilled with larger range of size. It is suitable for using in both production and maintenance shops 1. Easy operation. 2. Casting iron structure for long durability. 3. Column type of vertical drilling machine. 4. Worktable can rotate 180 degree and tilt 45 degree 5.Worktable lifting both manual and motorized.

2 speed strong power motor, 18 steps speed which can improve the machining accuracy and producing efficiency. 2 steps power feed 0.1-0.2mm/rev Drilling, tapping, boring, reaming; Automatic tools ejectors Strong column, table can rotary and tilting, Gear drive, lower noise;

2 speed strong power motor, 18 steps speed which can improve the machining accuracy and producing efficiency. Steps power feed 0.05-0.3mm/rev Drilling, tapping, boring, reaming; Automatic tools ejectors Strong column, table can rotary and tilting, Gear drive, lower noise;

Drilling, milling and tapping Head swivels 360 degree horizontally Headstock and Worktable up & down perpendicularly Super high column Precision micro feed Positive spindle lock Distinct auto device for releasing tools, operate easily Geared drive, lower noise

Drilling, milling and tapping Worktable can move X Y Z axis Head swivels 360 degree horizontally Headstock and Worktable up & down perpendicularly Super high column Precision micro feed Positive spindle lock Distinct auto device for releasing tools, operate easily Geared drive, lower noise

Drilling, milling and tapping Worktable can move X Y Z axis Head swivels 360 degree horizontally Headstock and Worktable up & down perpendicularly Super high column Precision micro feed Positive spindle lock Distinct auto device for releasing tools, operate easily Geared drive, lower noise