PRODUCTS

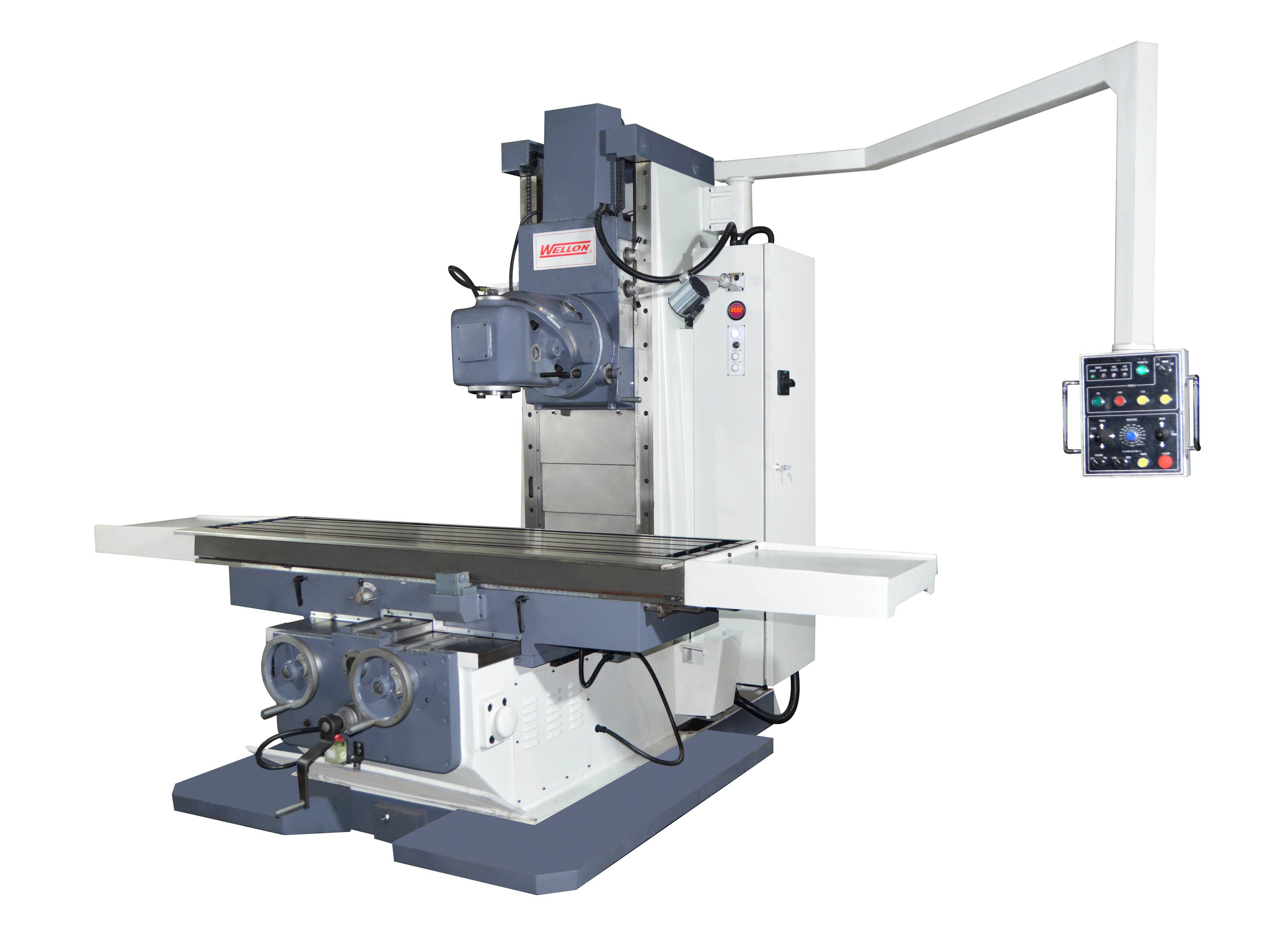

Only the cutter head (with the part) - not the machine table - moves on the Z axis. This results in improved stability, less vibration, and ultimately in increases precision and extremely high table load capacity! This effect is emphasized even more by the large, heavy cast-iron frame (Meehanite) and extremely wide box ways. Infinitely variable speed adjustment provided through frequency drive Rigid rectangular guideways for long-lasting accuracy Mehanite cast-iron frame cutter head swivels ± 30° hardened and ground guideways on all axes

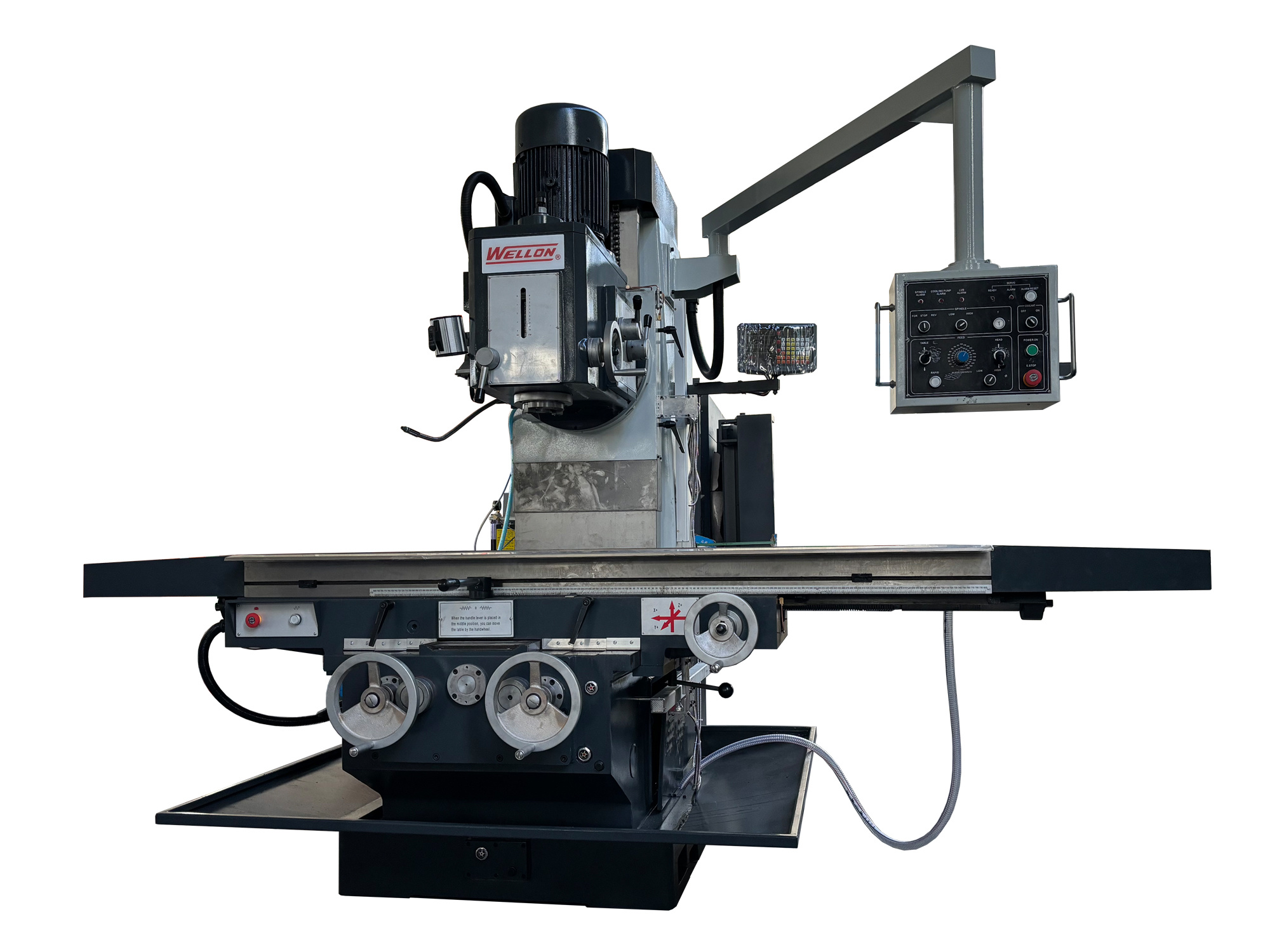

1)MEEHANITE cast-iron construction. 2)Rectangular guideways Y,Z axis with high rigidity. 3)Hardened and ground table surface. 4)Spindle is driven by gears. 5)12 steps spindle speed, the machine is applied to heavy cut. 6)Headstock swivels 30 degree.

An extremely rigid, large-sized box-column design, made of premium cast-iron Extra wide guideways ensure maximum stability and precision at high loads Extra long table travel distance (1500 mm) and large table set-up area (2100 x 500 mm) allow machining of large single parts or interactive machining of several parts - to give you a leading edge over your competition Wide spindle speed range from 40 to 1600 rpm Infinitely variable linear and cross feed Control panel on a long extending arm that can be ideally positioned by the operator This universal cutter head features maximum rigidity and quiet operation. The angle can be set manually on an infinitely adjustable scale from 90º to 45º. This allows an exact adjustment of the headstock in user-defined spatial angles and easy movement to a horizontal position. Includes a horizontal cutter arbor holder with excellent rigidity, allowing the user to fully utilize the advantages of a bed-type milling machine design for machining with long cutter arbors.

3 AXIS TRAVEL CAN REACH 2500X1020X1090MM MILLING HEAD SWIVEL 360 DEGREES MAX. SAFETY LOADING OF WORKPIECE CAN REACH 5000KG STRONG AND STABLE MILLING CAPACITY