PRODUCTS

1.All the components of the machine are designed under the instruction of the computer aided design and software of CAD/CAE/CAM to fully guarantee the intensity and rigidity of all the components. 2. All machine body is total monoblock welded assembly by high quality steels . After welding procedure, the machine body will be milled to ensure the balance and precision. 3. Mechanical synchronous mechanism and the complex compensation are designed so as to raise the work pieces precision. 4. Adopt integrated hydraulic system, more reliable and easy for maintenance. 5. The stroke and distance of the backgauge is adjusted by the motor and is well adjusted by hand,the adjustment is displayed by digital meters 6. Inch, single, continuous operation mode being designed for the machine and reversing and maintain time can be controlled by the time relays

1.All the components of the machine are designed under the instruction of the computer aided design and software of CAD/CAE/CAM to fully guarantee the intensity and rigidity of all the components. 2. All machine body is total monoblock welded assembly by high quality steels . After welding procedure, the machine body will be milled to ensure the balance and precision. 3. Mechanical synchronous mechanism and the complex compensation are designed so as to raise the work pieces precision. 4. Adopt integrated hydraulic system, more reliable and easy for maintenance. 5. The stroke and distance of the backgauge is adjusted by the motor and is well adjusted by hand,the adjustment is displayed by digital meters 6. Inch, single, continuous operation mode being designed for the machine and reversing and maintain time can be controlled by the time relays

NC Hydraulic Metal Plate Bending Machine Standard Press Brake Related Equipment: 1. Chinese E21 NC controller. 2. Y-axis and X-axis system control adjustment and frequency converter controls the positioning of them. 3. Linear guide rail and ball screw accuracy of 0.01mm(HIWIN,TAIWAN). 4. Steel mono-block construction. 5. Adjustable stop fingers. 6. Standard electrics from Schneider, France. 7. Standard oil tube connectors from EMB Germany. 8. Standard valves and oil pump from Bosch Rexroth Germany. 9. Standard main motor from Siemens Germany. 10. Hydraulic and electrical overload protection. 11. Light guards ensure the safety of operators during operation.

1. Main Features: Streamlined design originated from EU, heat treatment of machine frame, high rigidity workbench, optional mechanical compensation device, to ensure the precision of bending Hydraulic synchronous control and CNC programmable controller guarantee precise repeatability and easy use. Integrated hydraulic system ( Germany Bosch Rexroth ) can be automatically switched to slow bending status. X ,Y-axis realize accurate positioning function through CNC CybTouch 6 controller programming and servo motor. Latest servo response hydraulic control technology, the machine tool is more stable and reliable. Optimal parameter ratio, best core configuration guarantee stable performance and more convenient for operation PBT series machine is equipped with single-axis backgauge system, single-axis bending angle system and V-axis compensation function combining with customized dies, any type irregular workpieces can be done 2. Main Configuration Touch 6 controller Controller controls and adjusts Y-axis and X-axis Servo drive and control positioning of X-axis and Y-axis Adopting HIWIN ball screw and linear guide rail, accuracy 0.05mm Front supporter bracket Germany Bosch Rexroth hydraulic valve block Germany EMB oil tube connector Germany Siemens main motor France Schneider electrics Hydraulic & electrical overload protection Upper and lower dies(86°, R0.6mm, material: 42CrMo) 3. Safety Standard: 1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009 Front Finger protection ( safety light curtain ) South Korea KACON pedal switch ( safety grade 4 ) Back metal safeguard, CE standard Safety relay monitor pedal switch, safety protection Safety standard ( 2006/42/EC) 4. CybTouch6 controller Large, vivid and high-contrast fully touch screen. Simple pages, clear display, large keys. Very simple single bends with EasyBend page. Complete programming allows efficient mass-production of parts with multiple bends. Online help and warning pop-ups make it a very user-friendly software. Available in many languages. Comfortable wireless software updating and data backup using PC or Notebook.

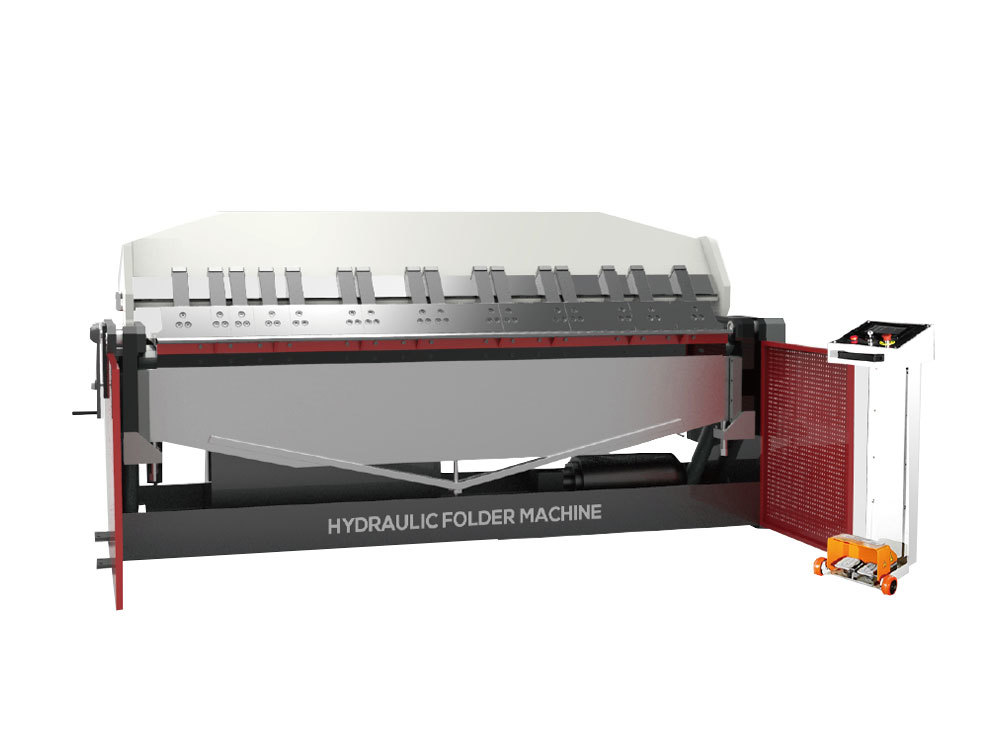

Features: NC Touch Screen Control features 99 programs, each program has up to 20 bends & each bend has material compensation. It’s also incorporates a quick bend function for jobbing work; Auto cycle: after clamping bottom beam will bend to pre-set angle and return, head unclamps to set position, NC programmable opening height & bending well timer ensures consistent bending angle; Quick action rapid head adjustment to optimize bend radius on 1-6mm material thickness; Heavy duty steel fabricated construction; Roving foot pedal incorporates control panel for maximum flexibility; Unique moving guards ensure the front of the machine is clear for unobstructed loading/unloading of material; Quality hydraulic and electrical components supplies by leading manufactures including Rexroth, Telemechanique and Merlin Gerin; Extended fingers al lows bending of pans or boxes to a depth of 205mm; Option CNC control back gauge or manual back gauge; Mild steel capacity is rated on hot rolled material with 250MPa.