PRODUCTS

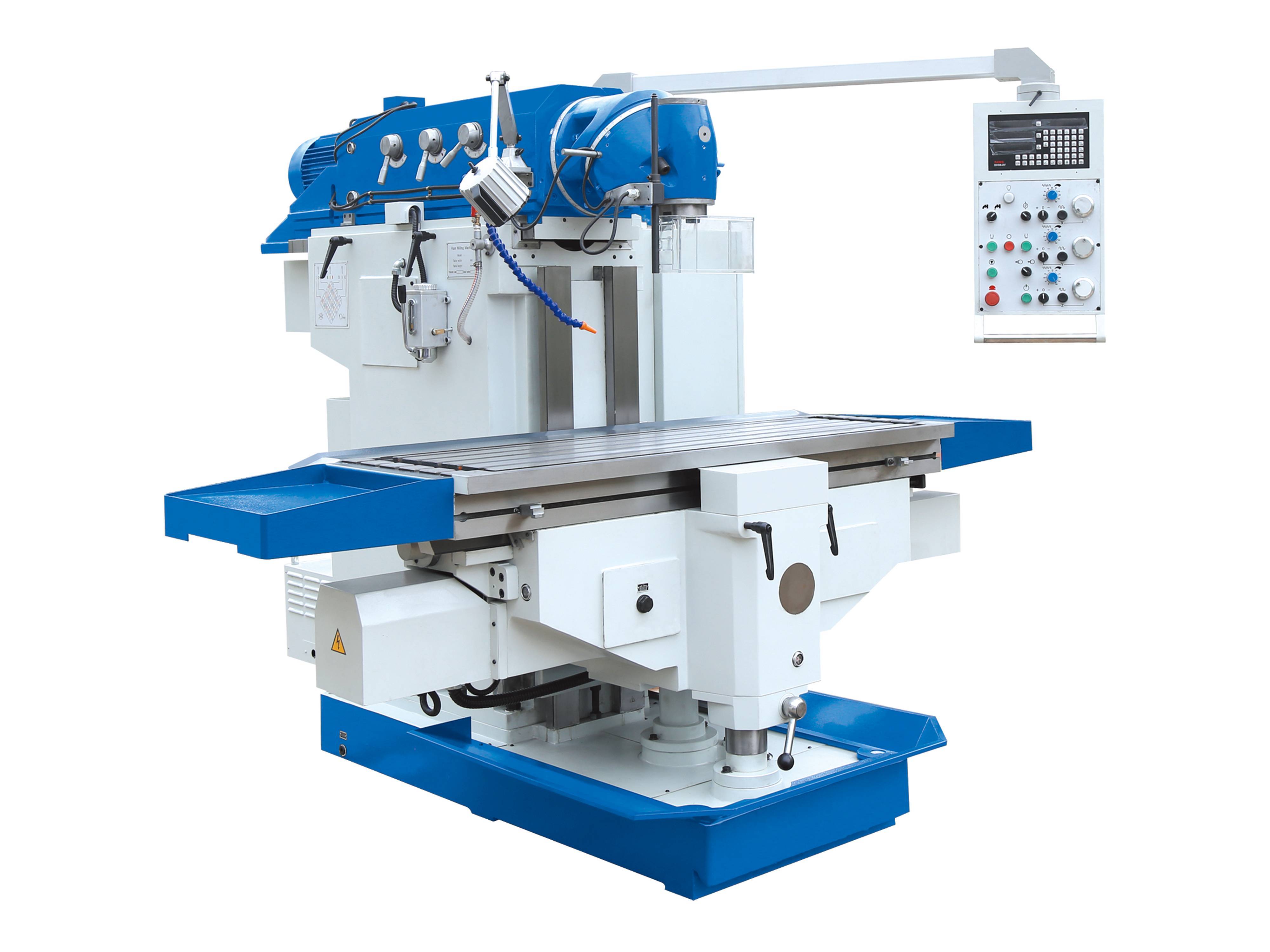

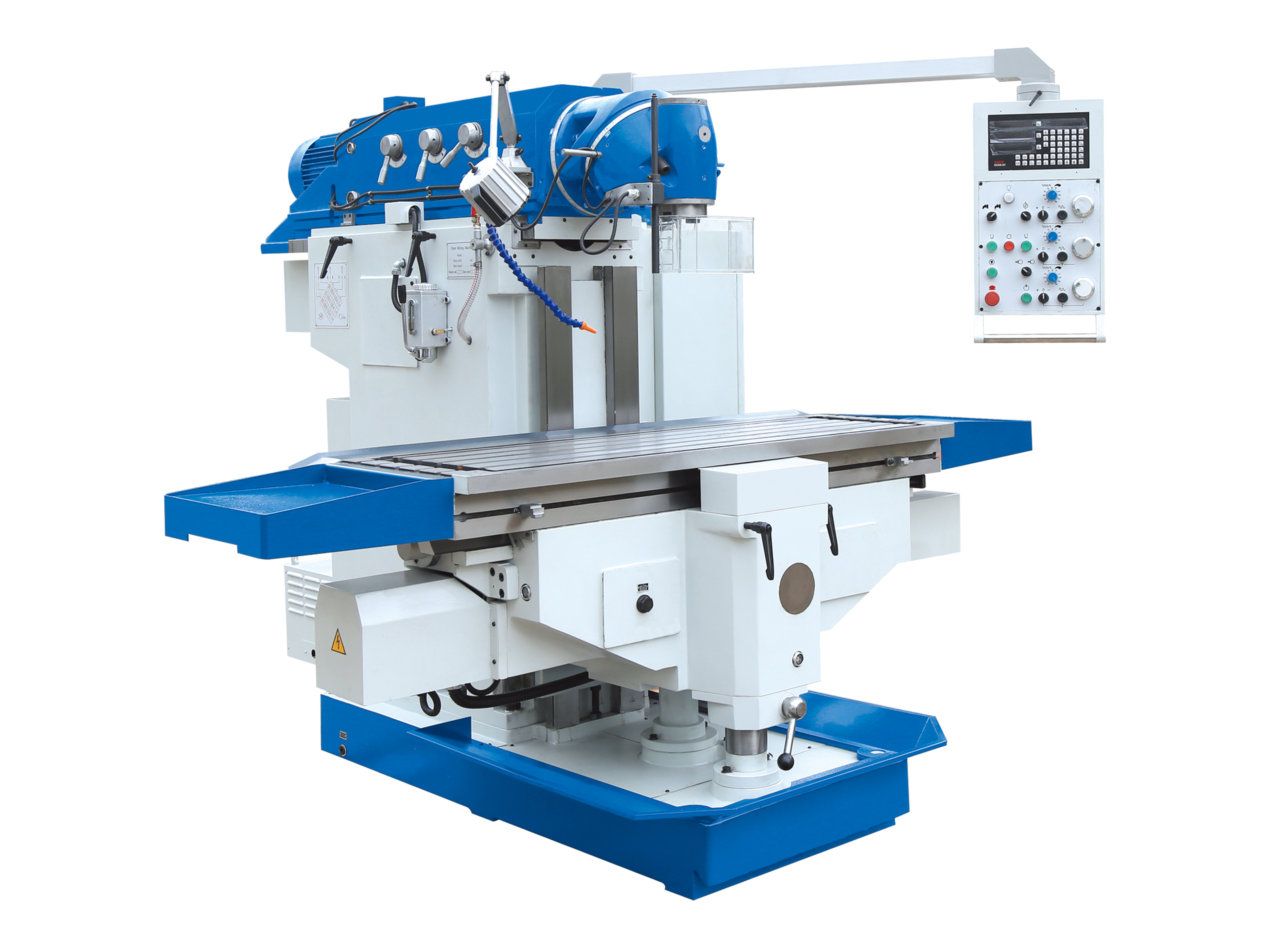

1. Ball screws can be ordered instead of standard lead screws at special request. 2. Vertical and Horizontal spindle hole taper both are ISO50. 3. The milling head can swivel at 360°. 4. Rotary table can be ordered at special request. 5. Worktable feed on X,Y,Z by manual or automatic. 6. Big worktable load. 7. CE standard can be chose. 8. Schneider electric can be ordered at special request. 9. More stronger type.

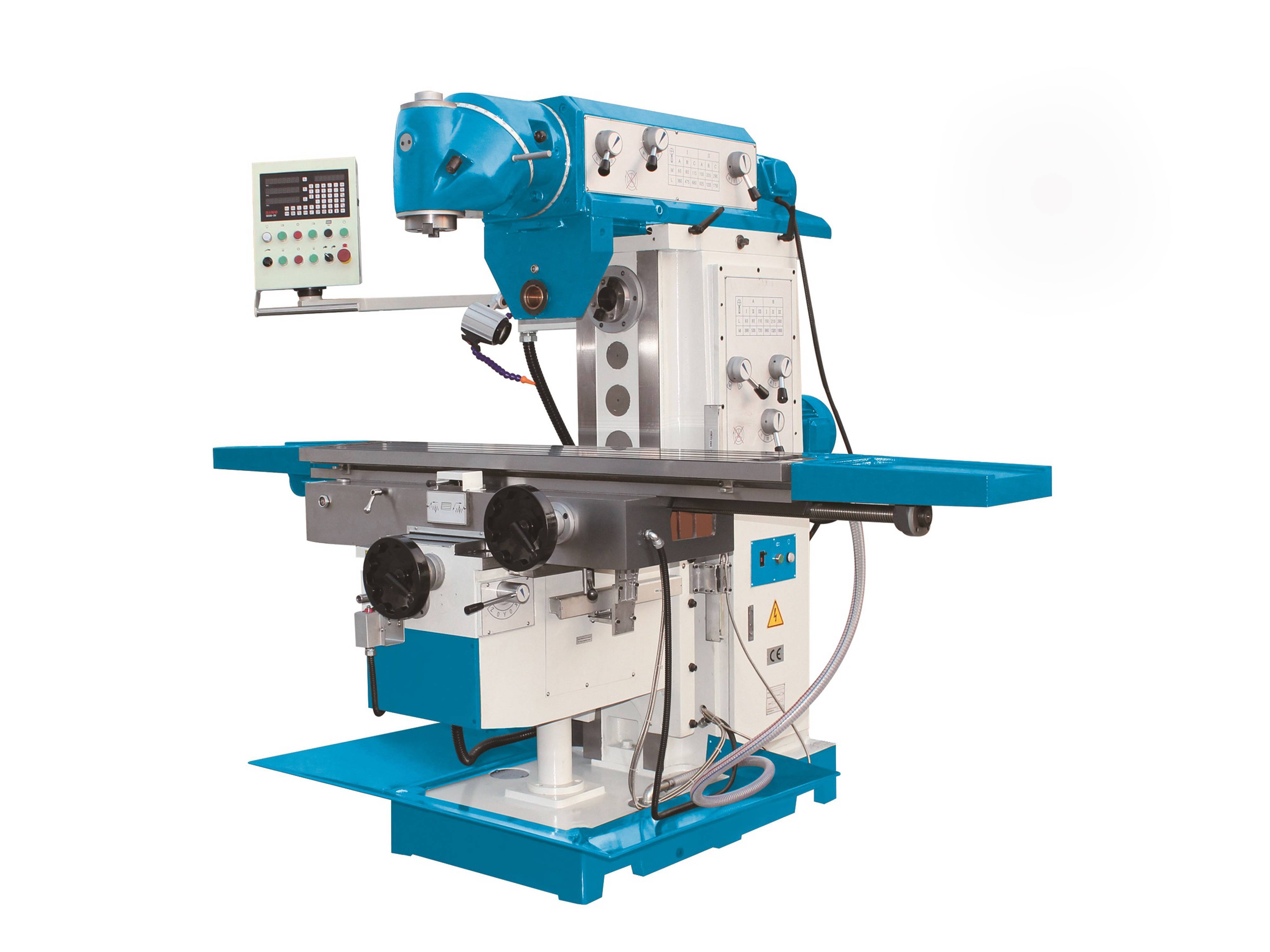

1.X,Y automatic feed through one gear box, Z lifting motor 2.head swivel 360 degrees 3.ram is movable 4.lubrication system

1.This milling machine is with universal milling head which can swivel 360 degrees 2.Ram can be movable forward and backward. 3.The machine is with dovetail guideway. 4.With X,Y axis auto power feed

1.X,Y automatic feed through one gear box, Z lifting motor 2.head swivel 360 degrees 3.ram is movable 4.lubrication system

1.This milling machine with universal milling head which can swivel 360 degress. 2.Optional rotary table 45°, Multi-angle processing. 3.Table 3 axes are controlled by one servo motor, toque large, energy efficiency, safe and reliable. 4.Hardened on x, y, z axis,rectangular guideway, stable, good rigidity.

1. This milling machine with universal milling head which can swivel 360 degress. 2. Optional rotary table 45°, Multi-angle processing. 3. Hardened on x, y, z axis,rectangular guideway, stable, good rigidity.

1. This milling machine with universal milling head which can swivel 360 degress. 2. Optional rotary table 45°, Multi-angle processing. 3. Hardened on x, y, z axis,rectangular guideway, stable, good rigidity.

1. This milling machine with universal milling head which can swivel 360 degress. 2. Optional rotary table 45°, Multi-angle processing. 3. Hardened on x, y, z axis,rectangular guideway, stable, good rigidity.

Logical, clearly arranged gearshift for speed change Hardened and polished guide ways guarantees top accuracy Setting of the required feed speed by potentiometer on the control panel Finely graduated feeds in all axis, driven by servo motor Universal mill head system ‘Huron’ adjusts to various angles Complete with rapid feed in x-, y- and z-axis to reduce downtime Optimal adjustments of spindle speed and feed allow for economic machining of various materials

Two joint type mill head can swivel 360degree, it is avaliable multi direction point of milling. X Y Z axis speed changed in fire-pin type, gear drive, auto feed. Servo motor controls X Y Z axis movement.

Table 3 axes with ball screws, high precision Table feeding with 3 separate servo motors, variable speeds, not interfere each other,high reliability,easy to operate Mechanical change speeds in head stock, powerful milling Table with an extra supporting column, big load, high accuracy It can mill any angle surface through front half-sphere by swiveling milling head Optional can be install CNC Controller: such as Siemens808D, Siemens828D

Table 3 axes with ball screws, high precision Table feeding with 3 separate servo motors, variable speeds, not interfere each other,high reliability,easy to operate Mechanical change speeds in head stock, powerful milling Table with an extra supporting column, big load, high accuracy It can mill any angle surface through front half-sphere by swiveling milling head Optional can be install CNC Controller: such as Siemens808D, Siemens828D

Table 3 axes with ball screws, high precision Table feeding with 3 separate servo motors, variable speeds, not interfere each other,high reliability,easy to operate Mechanical change speeds in head stock, powerful milling Table with an extra supporting column, big load, high accuracy It can mill any angle surface through front half-sphere by swiveling milling head Optional can be install CNC Controller: such as Siemens808D, Siemens828D

XL6430 XL6430A XL6430B XL6430C

1. X Y Z auto feed by Servo Motor 2. Universal swivel head can mill any angle surface through front half-sphere 3. Horizontal spindle with large speed range, suitable for low-speed heavy load process and high-speed precision process 4. 3-axis Digital Readout, Rotary table, Protective cover are available as optional

Logical, clearly arranged gearshift for speed change Hardened and polished guideways guarantees top accuracy Setting of the required feed speed by potentiometer on the contro panel Digital readout for x-, y- and z-axis come standard Finely graduated feeds in all axis, driven by servomotor Universal mill head system „Huron“ adjusts to various angles Complete with rapid feed in x-, y- and z-axis to reduce downtime Optimal adjustments of spindle speed and feed allow for economic machining of various materials Central lubrication in x- and y-axis comes standard

Logical, clearly arranged gearshift for speed change Hardened and polished guide ways guarantees top accuracy Setting of the required feed speed by potentiometer on the control panel Finely graduated feeds in all axis, driven by servo motor Universal mill head system ‘Huron’ adjusts to various angles Complete with rapid feed in x-, y- and z-axis to reduce downtime Optimal adjustments of spindle speed and feed allow for economic machining of various materials