PRODUCTS

1.Used for cutting all kinds of metal material 2.Reasonable structure,stable performance,high precision. 3.PLC control,high efficiency,automatic hydraulic bar feeder. 4.Upper hydraulic clamp for bundle cutting

1.Used for cutting all kinds of metal material 2.Reasonable structure,stable performance,high precision. 3.PLC control,high efficiency,automatic hydraulic bar feeder. 4.Upper hydraulic clamp for bundle cutting

1.Used for cutting all kinds of metal material 2.Reasonable structure,stable performance,high precision. 3.PLC control,high efficiency,automatic hydraulic bar feeder. 4.Upper hydraulic clamp for bundle cutting

1.Used for cutting all kinds of metal material 2.Reasonable structure,stable performance,high precision. 3.PLC control,high efficiency,automatic hydraulic bar feeder. 4.Upper hydraulic clamp for bundle cutting

1.Used for cutting all kinds of metal material 2.Reasonable structure,stable performance,high precision. 3.PLC control,high efficiency,automatic hydraulic bar feeder. 4.Upper hydraulic clamp for bundle cutting

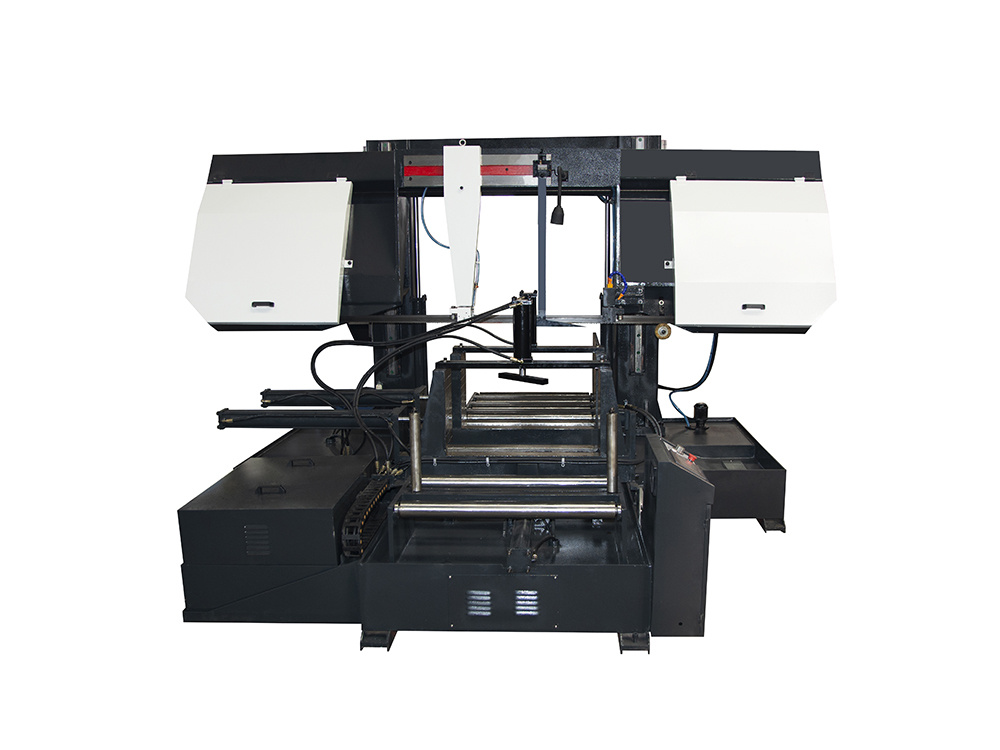

Solid steel saw frame within a dual-column frame linear guide Flat and low profile for easier handling of heavy or large workpieces Manual linear stop for quick and easy setting of the correct workpiece length Powerful drive motor The torsion-proof saw frame features an infinitely adjustable feed At the end of the sawing cycle, The frame will automatically return to the original position Hydraulic workpiece clamping included

Solid steel saw frame within a dual-column frame linear guide Flat and low profile for easier handling of heavy or large workpieces Manual linear stop for quick and easy setting of the correct workpiece length Powerful drive motor The torsion-proof saw frame features an infinitely adjustable feed At the end of the sawing cycle, The frame will automatically return to the original position Hydraulic workpiece clamping included

Solid steel saw frame within a dual-column frame linear guide Flat and low profile for easier handling of heavy or large workpieces Manual linear stop for quick and easy setting of the correct workpiece length Powerful drive motor The torsion-proof saw frame features an infinitely adjustable feed At the end of the sawing cycle, The frame will automatically return to the original position Hydraulic workpiece clamping included

1.Used for cutting all kinds of metal material 2.Reasonable structure,stable performance,high precision. 3.PLC control,high efficiency,automatic hydraulic bar feeder. 4.Upper hydraulic clamp for bundle cutting

GHS4228 GHS4230 GHS4235 GHS4240 GHS4250 GHS4260 GHS4265 GHS4270 GHS4280

1.Used for cutting all kinds of metal material 2.Reasonable structure,stable performance,high precision. 3.PLC control,high efficiency, 4.Automatic hydraulic bar feeder.

PLC program control, setting the cutting process. Grating position feeding length, single-precision feed control within 0.2mm. Processing size can be set to 1~5 groups. Each group can be set once the feed length 50000mm. Each group can be set once the number of processing elements is 1-999. Jaws around the same time release / clamping jaws easy to wear. Circulating hydraulic oil cooling system, the oil temperature is not easy to rise. Automatic saw blade sweep crumbs device to prevent the accumulation of sawdust in the jagged,effective protection band saw blades. Broken belt protection function, when the saw blade breaks or cassette, the machine can automatically shut down to protect the machine and workpiece. Clamping detachable hydraulic system that allows a plurality of multilayer workpiece while cutting.