PRODUCTS

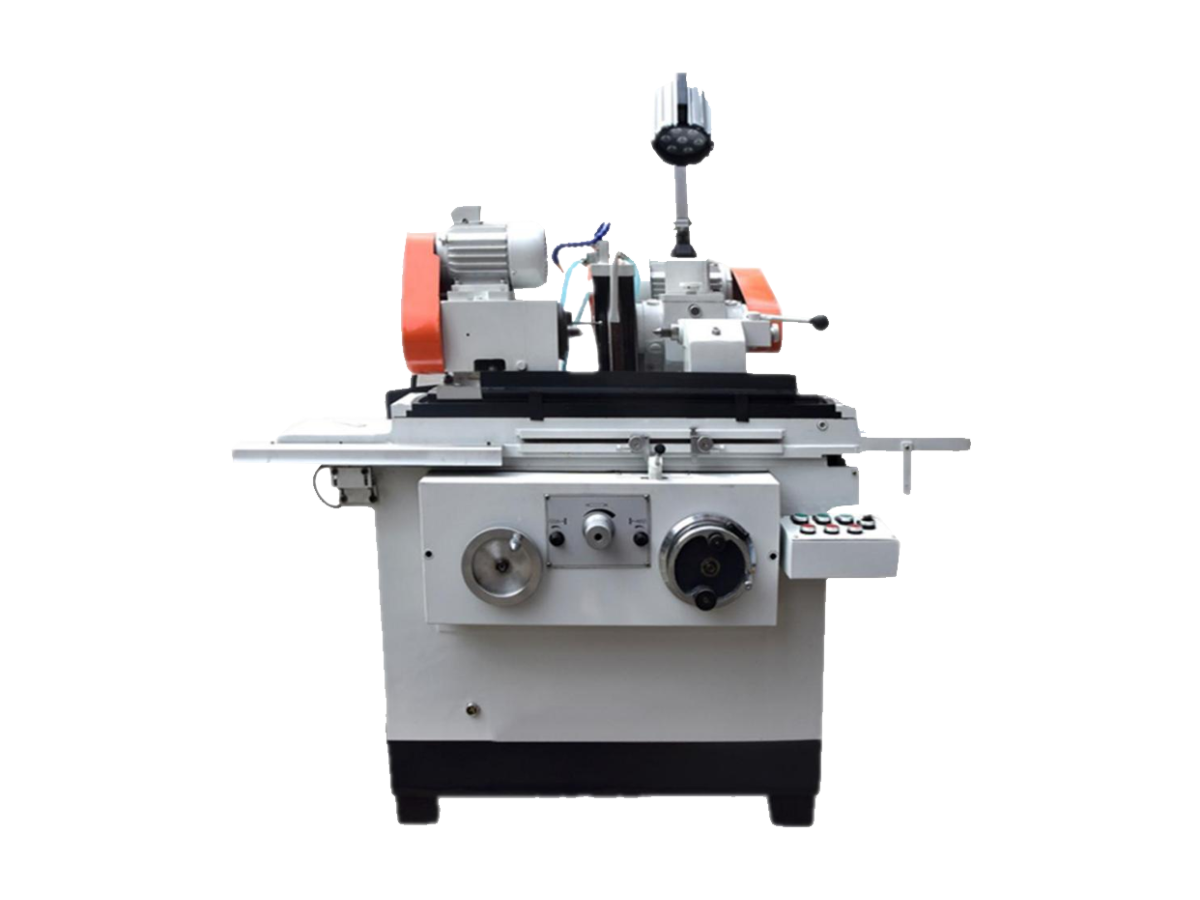

This machine is suitable for grinding cylindrical, conical shape internal, external and end face of various middle and small size work piece. With strong rigidity High precision High grinding efficiency. It has strong cutting function Rigid Grinding head has the certain cutting edge Applicable to small batch production in the workshop and the use of the tool machine shop

This machine is suitable for grinding cylindrical, conical shape internal, external and end face of various middle and small size work piece. With strong rigidity High precision High grinding efficiency. It has strong cutting function Rigid Grinding head has the certain cutting edge Applicable to small batch production in the workshop and the use of the tool machine shop

This machine is suitable for grinding cylindrical, conical shape internal, external and end face of various middle and small size work piece. With strong rigidity High precision High grinding efficiency. It has strong cutting function Rigid Grinding head has the certain cutting edge Applicable to small batch production in the workshop and the use of the tool machine shop

This machine is suitable for grinding cylindrical, conical shape internal, external and end face of various middle and small size work piece. With strong rigidity High precision High grinding efficiency. It has strong cutting function Rigid Grinding head has the certain cutting edge Applicable to small batch production in the workshop and the use of the tool machine shop

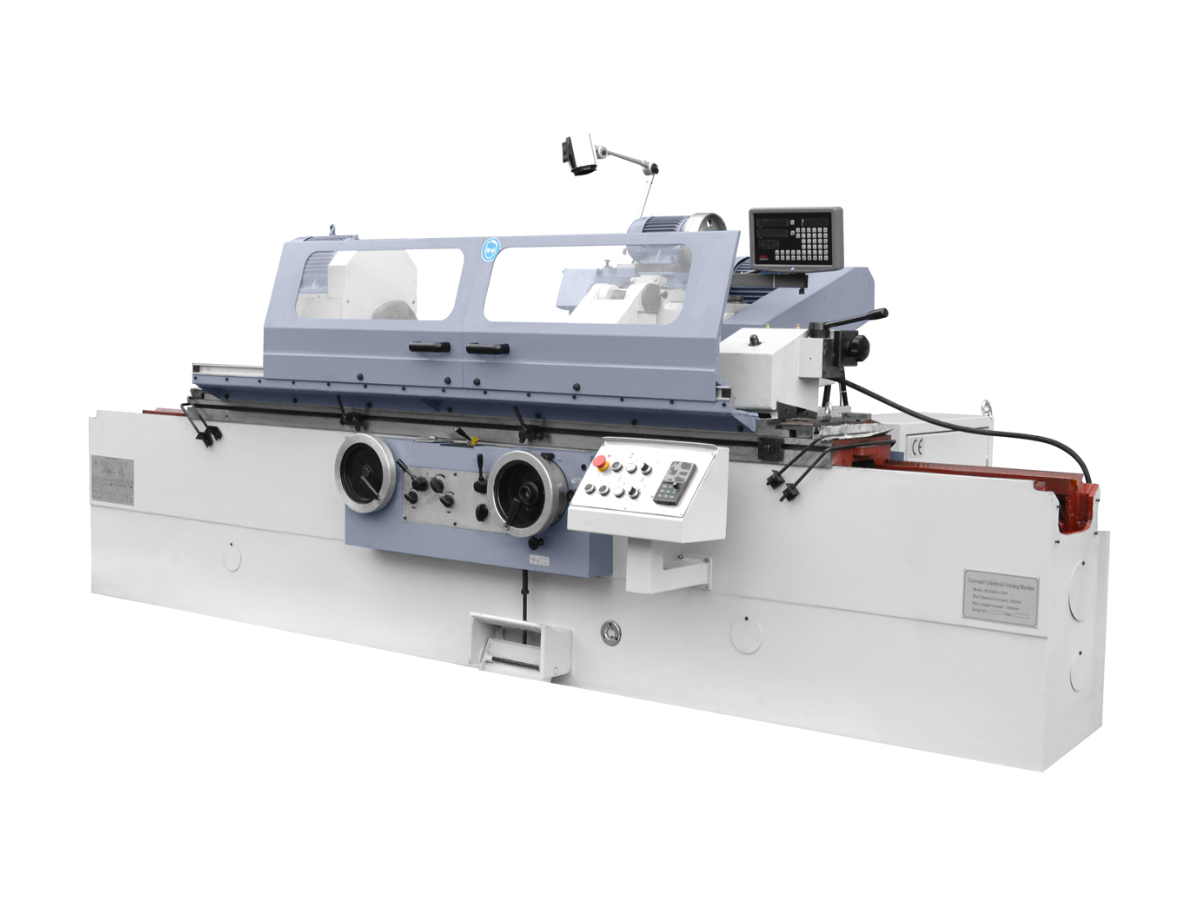

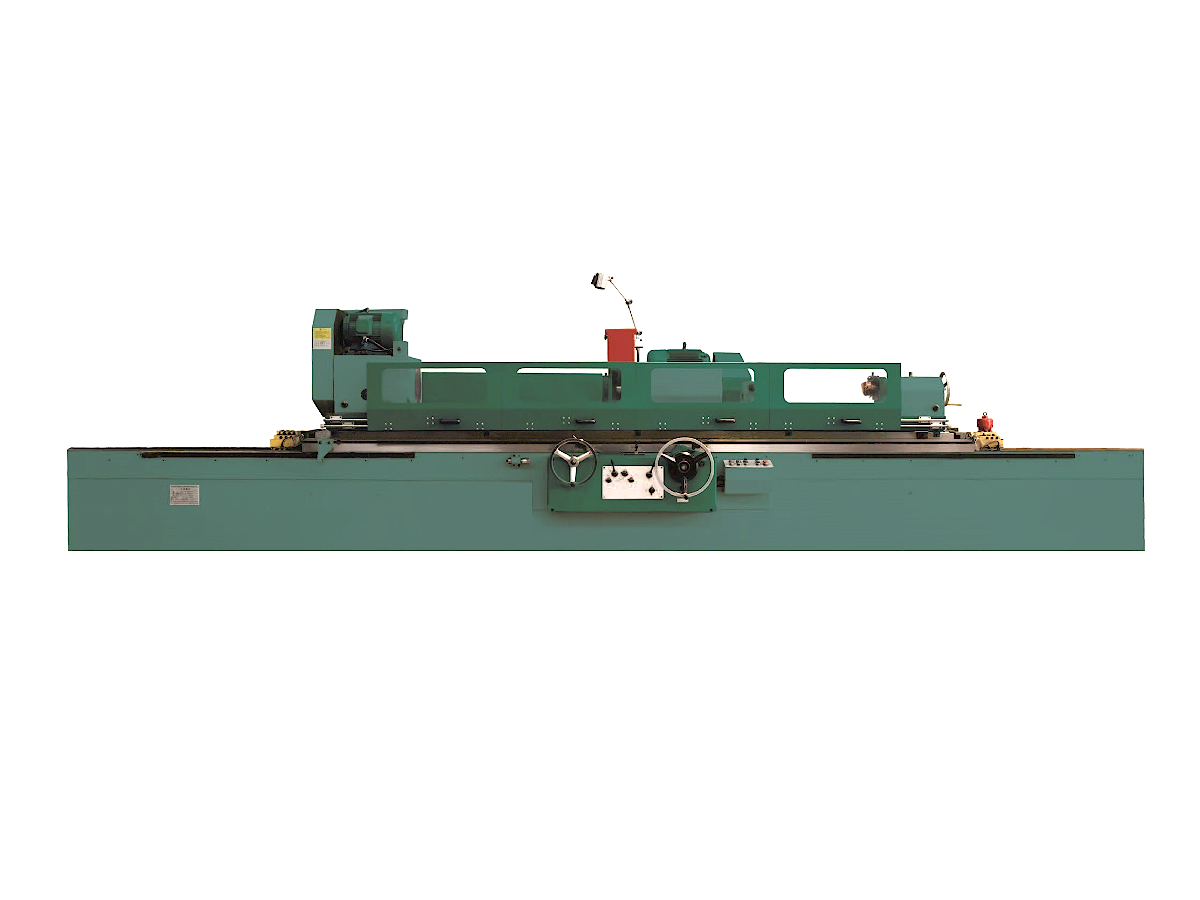

Suitable for grinding IT6-IT5 accuracy cylindrical conical parts Can choose hydraulic stepless or hand wheel transmission to achieve worktable longitudinal movement Adopt orifice compensated unloading form on worktable lubrication With hydraulic fast feed,manual micro feed and wheel automatic cycle feed function on worktable cross travel Workpiece,External Grinding wheel,Oil pump,and Coolant pump are driven by independent motors Adopt 2 sets of 4 bearing bushes compose the wheel spindle bearing.Increase the grinding carriage spindle diameter and motor power.Improve the grinding efficiency Wheel dresser mounted on the tailstock,and tailstock equipped with hydraulic center back device Adopt interlocking mechanism among electric,hydraulic and mechanical part,ensure safe operation.

Via linear hydraulic feed Solid workpiece spindle head and wide, rigid grinding spindle support with inside grinder ensure the best possible results under varying operating conditions grinding spindle supported on both sides in an adjustable 3-segment bushing a dwell time can be set at the end of the table travel The sturdy spindle head swivels 30° to the left and the right Pawl-feed in combination with a zero-stop allows repeated feed without checking the feed scale including inside grinding feature and automatic infeed hydraulic or manual rapid feed with return infinitely variable feed

1. When conical grinding, the table can be swiveled to either side and exactly positioned by using the scale 2. Oil film between bearing and spindle keeps vibrations at a minimum level, hence achieving outstanding results and top accuracy 3. Precisely balanced spindle head and solid grinding head guarantee extraordinary results at any type of operation 4. Strong reinforcements and solidly designed panels of the machine base makes it resistant to temperature fluctuations and deformations 5. Spindle is mounted from both sides and features adjustable sliding bearings consisting of three segments 6. Hydrodynamic bearing of spindle, therefore no contact between spindle and bearing 7. Longitudinal table feed can be set to automatic mode -hydraulically driven or manual mode - by hand wheel 8. Stepless feed adjustments with the option of aprogrammable hold time at the end of each table movement 9. Hydraulic or manual repositioning of grinding spindle stock 10.Guide ways in x- and y-axis are precisely constructed and hand-polished 11.Longitudinal table guide and cross guide of grinding headstock each feature a V-guide and flat guide

Via linear hydraulic feed Solid workpiece spindle head and wide, rigid grinding spindle support with inside grinder ensure the best possible results under varying operating conditions grinding spindle supported on both sides in an adjustable 3-segment bushing a dwell time can be set at the end of the table travel The sturdy spindle head swivels 30° to the left and the right Pawl-feed in combination with a zero-stop allows repeated feed without checking the feed scale including inside grinding feature and automatic infeed hydraulic or manual rapid feed with return infinitely variable feed

A hydro-dynamic system produces an oil film between bushing and spindle to reduce vibration ensuring maximum precision and surface quality. This type of bearing increase the spindle's life and stability The table features large dimensions and swivels in two directions - table movement via hand-wheel or automatically via linear hydraulic feed Very solid workpiece spindle head and wide, rigid grinding spindle support with inside grinder ensure the best possible results under varying operating conditions Grinding spindle supported on both sides in an adjustable 3-segment bushing A dwell time can be set at the end of the table travel Accuracy tested in accordance with ISO for cylindrical grinding machines The sturdy spindle head swivels 30° To the left and the right Pawl-feed in combination with a zero-stop allows repeated feed without checking the feed scale Including inside grinding feature and automatic infeed Hydraulic or manual rapid feed with return Infinitely variable feed

A hydro-dynamic system produces an oil film between bushing and spindle to reduce vibration ensuring maximum precision and surface quality. This type of bearing increase the spindle's life and stability The table features large dimensions and swivels in two directions - table movement via hand-wheel or automatically via linear hydraulic feed Very solid workpiece spindle head and wide, rigid grinding spindle support with inside grinder ensure the best possible results under varying operating conditions Grinding spindle supported on both sides in an adjustable 3-segment bushing A dwell time can be set at the end of the table travel Accuracy tested in accordance with ISO for cylindrical grinding machines The sturdy spindle head swivels 30° To the left and the right Pawl-feed in combination with a zero-stop allows repeated feed without checking the feed scale Including inside grinding feature and automatic infeed Hydraulic or manual rapid feed with return Infinitely variable feed

A hydro-dynamic system produces an oil film between bushing and spindle to reduce vibration ensuring maximum precision and surface quality. This type of bearing increase the spindle's life and stability The table features large dimensions and swivels in two directions - table movement via hand-wheel or automatically via linear hydraulic feed Very solid workpiece spindle head and wide, rigid grinding spindle support with inside grinder ensure the best possible results under varying operating conditions Grinding spindle supported on both sides in an adjustable 3-segment bushing A dwell time can be set at the end of the table travel Accuracy tested in accordance with ISO for cylindrical grinding machines The sturdy spindle head swivels 30° To the left and the right Pawl-feed in combination with a zero-stop allows repeated feed without checking the feed scale Including inside grinding feature and automatic infeed Hydraulic or manual rapid feed with return Infinitely variable feed

The machine can grind cylindrical and conical external surfaces and holes with accuracy of IT6 and IT5. The longitudinal travel of the worktable and the in-feed of the wheel head are carried out hydraulically or manually. The rapid approach and withdrawal of the tailstock center, the lubrication of the worktable slide-way and the in-feed lead screw etc, are all hydraulically controlled. The electro system have been designed according to the CE standard All the electro parts adopted world brand or Chinese famous brand, such as the Siemens, schneider, Delixi, Juche, etc. For AHD model, the spindle elevating motor adopt Servo motor made in Japan ( Panasonic), and controlled by Siemens PLC. The operator can set the Auto working (feed rate and times, spark grinding times by the control panel. When finish grinding, the spindle will lift up auto. The high precision spindle unit is well designed and produced high load resistible, mounted in pre-loaded angular deep-groove ball bearing ensures low-vibration operation, high accuracy, increased lifetime, and low maintenance The vertical lift lead screw is made in Taiwan, Name: SHYH MINMACHINERY The Cross feed screw is Ball screw ( SGA30~40 series), make sure the smooth moving. AC motor drove the cross screw by timing belt then realize auto intermittent feed. The spindle Motor, Y axis drove Motor, and other important parts, Are all made by famous specialty manufacturer, SHVH MIN, Juli, Shuanglin etc... Carefully painting. Pay more attention to the round corner, straight border. Elaborate work make the machine with not only good accuracy but also nice appearance. The surface grinding machine with pleasing appearance and well designed structure, the machine is an indeed precision grind equipment for metal working. Also it can be equipped with optional accessories, such as parallel wheel dresser, magnetic separate coolant unit, etc

A hydro-dynamic system produces an oil film between bushing and spindle to reduce vibration ensuring maximum precision and surface quality. This type of bearing increase the spindle's life and stability The table features large dimensions and swivels in two directions - table movement via hand-wheel or automatically via linear hydraulic feed Very solid workpiece spindle head and wide, rigid grinding spindle support with inside grinder ensure the best possible results under varying operating conditions Grinding spindle supported on both sides in an adjustable 3-segment bushing A dwell time can be set at the end of the table travel Accuracy tested in accordance with ISO for cylindrical grinding machines The sturdy spindle head swivels 30° To the left and the right Pawl-feed in combination with a zero-stop allows repeated feed without checking the feed scale Including inside grinding feature and automatic infeed Hydraulic or manual rapid feed with return Infinitely variable feed

A hydro-dynamic system produces an oil film between bushing and spindle to reduce vibration ensuring maximum precision and surface quality. This type of bearing increase the spindle's life and stability The table features large dimensions and swivels in two directions - table movement via hand-wheel or automatically via linear hydraulic feed Very solid workpiece spindle head and wide, rigid grinding spindle support with inside grinder ensure the best possible results under varying operating conditions Grinding spindle supported on both sides in an adjustable 3-segment bushing A dwell time can be set at the end of the table travel Accuracy tested in accordance with ISO for cylindrical grinding machines The sturdy spindle head swivels 30° To the left and the right Pawl-feed in combination with a zero-stop allows repeated feed without checking the feed scale Including inside grinding feature and automatic infeed Hydraulic or manual rapid feed with return Infinitely variable feed

The machine can grind cylindrical and conical external surfaces and holes with accuracy of IT6 and IT5. The longitudinal travel of the worktable and the in-feed of the wheel head are carried out hydraulically or manually. The rapid approach and withdrawal of the tailstock center, the lubrication of the worktable slide-way and the in-feed lead screw etc, are all hydraulically controlled. The electro system have been designed according to the CE standard All the electro parts adopted world brand or Chinese famous brand, such as the Siemens, schneider, Delixi, Juche, etc. For AHD model, the spindle elevating motor adopt Servo motor made in Japan ( Panasonic), and controlled by Siemens PLC. The operator can set the Auto working (feed rate and times, spark grinding times by the control panel. When finish grinding, the spindle will lift up auto. The high precision spindle unit is well designed and produced high load resistible, mounted in pre-loaded angular deep-groove ball bearing ensures low-vibration operation, high accuracy, increased lifetime, and low maintenance The vertical lift lead screw is made in Taiwan, Name: SHYH MINMACHINERY The Cross feed screw is Ball screw ( SGA30~40 series), make sure the smooth moving. AC motor drove the cross screw by timing belt then realize auto intermittent feed. The spindle Motor, Y axis drove Motor, and other important parts, Are all made by famous specialty manufacturer, SHVH MIN, Juli, Shuanglin etc... Carefully painting. Pay more attention to the round corner, straight border. Elaborate work make the machine with not only good accuracy but also nice appearance. The surface grinding machine with pleasing appearance and well designed structure, the machine is an indeed precision grind equipment for metal working. Also it can be equipped with optional accessories, such as parallel wheel dresser, magnetic separate coolant unit, etc

1, mainly used for grinding small shaft, circle, needle valve, plunger set of cylinder and cone surface 2, tooling way available top, three jaw chuck, and special fixture of spring clip; 3, apply to instrumentation, automotive electrical and mechanical, bearings, textile, Marine, sewing machines, machinery and other industries processing small parts, 4, vertical moving workbench hydraulic and manual, grinding wheel rack and head are rotating, hydraulic system USES the good performance of the gear, 5, suitable for tools, machine shop and workshop for medium and small batch production, 6, the machine according to the top is divided into 300 mm.

1, mainly used for grinding small shaft, circle, needle valve, plunger set of cylinder and cone surface 2, tooling way available top, three jaw chuck, and special fixture of spring clip; 3, apply to instrumentation, automotive electrical and mechanical, bearings, textile, Marine, sewing machines, machinery and other industries processing small parts, 4, vertical moving workbench hydraulic and manual, grinding wheel rack and head are rotating, hydraulic system USES the good performance of the gear, 5, suitable for tools, machine shop and workshop for medium and small batch production, 6, the machine according to the top is divided into 300 mm.