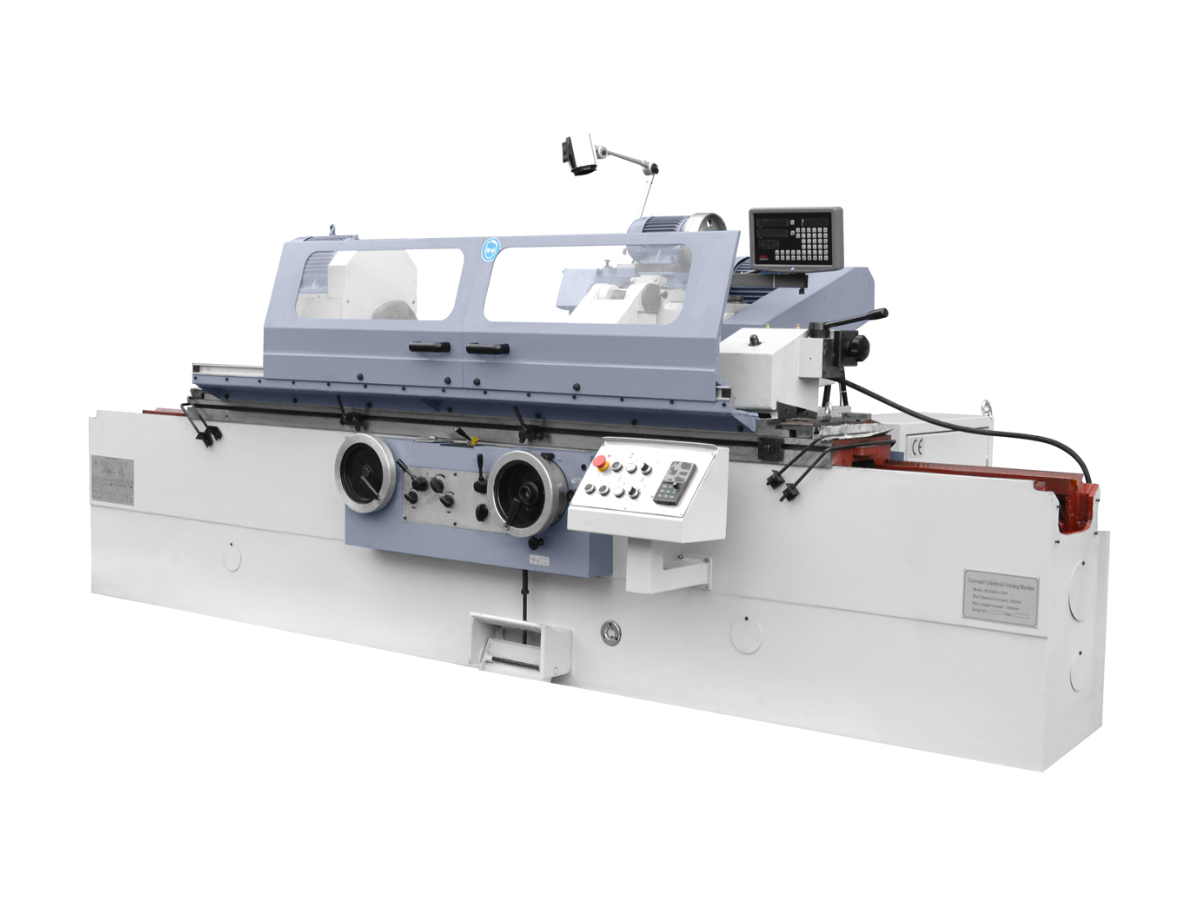

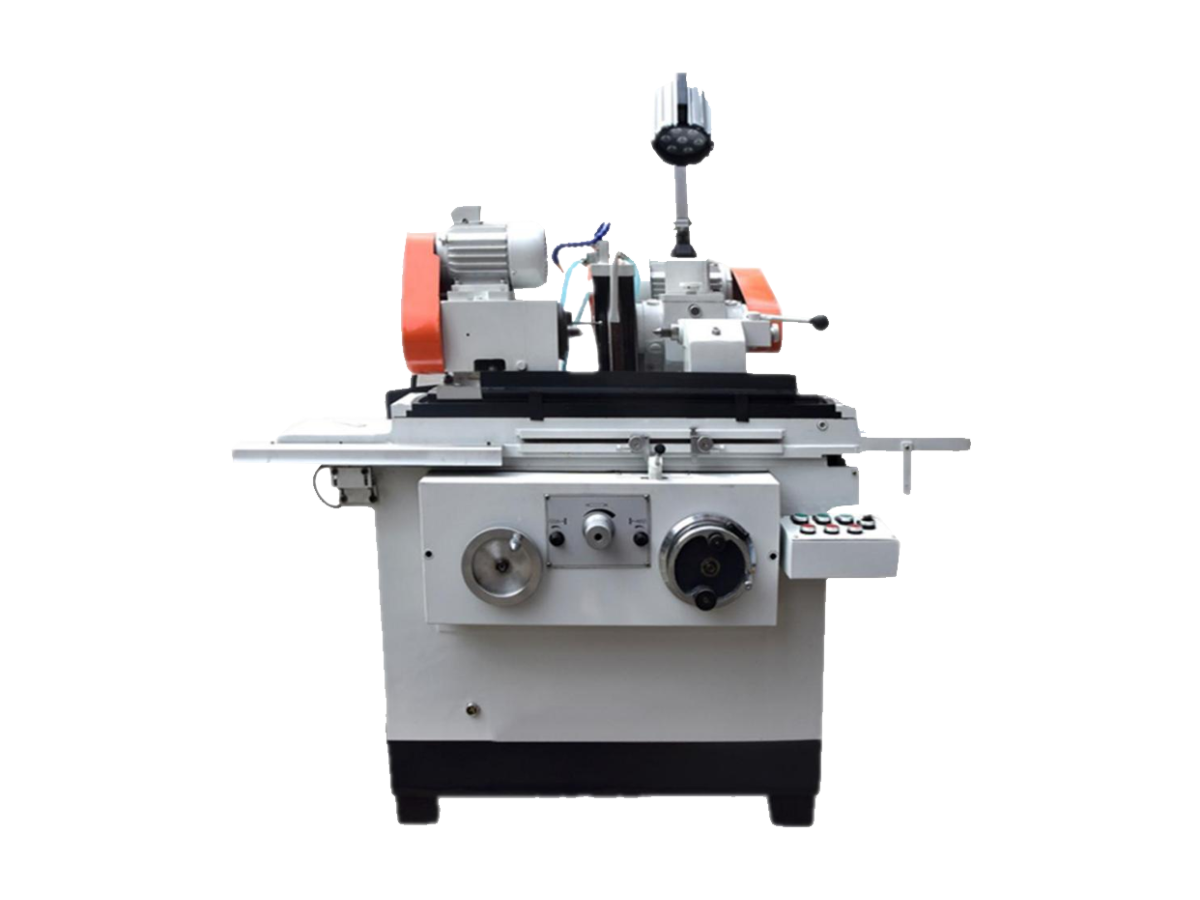

M1432

Classification:

keyword:

Cylinder grinding

WhatsApp:+86-13969473068

- Details

- Standard accessories

- Optional accessories

-

- 商品名称: M1432

The machine can grind cylindrical and conical external surfaces and holes with accuracy of IT6 and IT5. The longitudinal travel of the worktable and the in-feed of the wheel head are carried out hydraulically or manually. The rapid approach and withdrawal of the tailstock center, the lubrication of the worktable slide-way and the in-feed lead screw etc, are all hydraulically controlled. The electro system have been designed according to the CE standard All the electro parts adopted world brand or Chinese famous brand, such as the Siemens, schneider, Delixi, Juche, etc. For AHD model, the spindle elevating motor adopt Servo motor made in Japan ( Panasonic), and controlled by Siemens PLC. The operator can set the Auto working (feed rate and times, spark grinding times by the control panel. When finish grinding, the spindle will lift up auto. The high precision spindle unit is well designed and produced high load resistible, mounted in pre-loaded angular deep-groove ball bearing ensures low-vibration operation, high accuracy, increased lifetime, and low maintenance The vertical lift lead screw is made in Taiwan, Name: SHYH MINMACHINERY The Cross feed screw is Ball screw ( SGA30~40 series), make sure the smooth moving. AC motor drove the cross screw by timing belt then realize auto intermittent feed. The spindle Motor, Y axis drove Motor, and other important parts, Are all made by famous specialty manufacturer, SHVH MIN, Juli, Shuanglin etc... Carefully painting. Pay more attention to the round corner, straight border. Elaborate work make the machine with not only good accuracy but also nice appearance. The surface grinding machine with pleasing appearance and well designed structure, the machine is an indeed precision grind equipment for metal working. Also it can be equipped with optional accessories, such as parallel wheel dresser, magnetic separate coolant unit, etc

MAIN SPECIFICATION

UNIT

MW1420

M1432

General capacity

Distance between centers

mm

500/750

1000

Center height

mm

125

180

Dia.Ground (O.D)

mm

8-200

8~320

Dia.Ground (I.D)

mm

13-80

30~100

Max.length ground (O.D)

mm

500/750

1000

Max.length ground (I.D)

mm

125

125

Max.weight of work piece

kg

100

150

Workhead

Swiveling angle

+90°

+90

Center taper (MT)

MT

4

4

Spindle speed

r/min

25-380

50HZ:25-220

60HZ:30-364Wheelhead

Wheel spindle speed

r/min

1670

1670

Wheelhead rapid travel

mm

50

50

Max.travel

mm

205

246

Swiveling angel

+10°

±30°

Hand feed per.rev

mm

Rough:2 fine:0.5

rough:2.0

fine:0.5Hand feed per.gra

mm

Rough:0.01 fine:0.05

rough:0.01

fine:0.0025Wheel size (ODxWxID)

mm

400x50x203

400×50×203

Internal grinding device

Spindle speed

r/min

10000

10000/15000

Dimension of wheel

mm

max:50x25x13, min:17x20x6

max:50×25×13

min:17×20×6Table

Hand feed per.rev

mm

6

6

Max.swiveling angle of table

°

clockwise:3°

widdershins:7°clockwise:3°

widdershins:7°Longitudinal speed range of table

m/min

0.1-4

0.1~4

Tailstock

Center taper (MT)

MT

4

4

Quil travel

mm

30

30

Motor

Wheelhead motor power

kw

1.1

5.5

Internal grinding

kw

1.1

1.1

Workhead motor power

kw

1.1

1.5

Machine

Gross weight

kg

4.1(500)

9900

Packing dimension

cm

235x203x205(500)

739×228×205

-

Standard grinding wheel

Coolant tank

Wheel dresser

Wheel flanges

Wheel balancing mandrel

Three jaw chuck

Open type steady rest

Driving dog

Carbide tipped center

Support

Chuck base

-

Magnetic separator

Coolant tank with paper filter

Center rest close type

Radius dresser

Wheel balancing stand

RELATED PRODUCTS