PRODUCTS

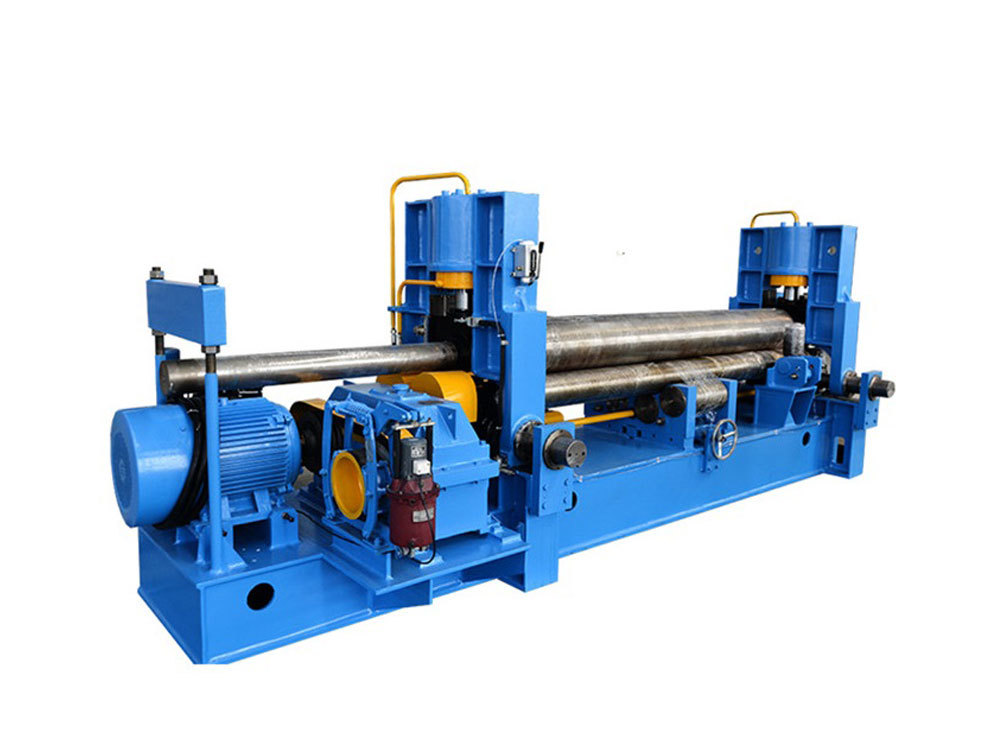

Mechanical symmetrical rolling machine is a kind of three roller asymmetric rolling equipment. The upper roll moves vertically in the center between the two lower rolls. The two lower rolls rotate and provide the plate materials with torque. The mechanical plate bending machinery consists of two parts, the operation part and the transmission part which are welded at the whole bottom pallet. It features compact structure, easy operation and convenient maintenance. Mechanical symmetrical rolling machine is mainly used in the process of cold working in which the sheets within the thickness of 12 mm can be bent into cylindrical tubes with different diameters. The mechanical plate bending machinery is widely used in boiler, chemical industry, mining, construction, shipbuilding and other machinery industries.

The upper roller universal plate rolling machinery can be mainly used for rolling the certain plates into the form of drum and arc. The basic working principle for this plate bending machine is to curve and roll. Rotating bending deformation is the core working procedure. It can also be applied in petroleum, chemical industry, cement, boiler, shipbuilding, aviation, water conservancy, power transmission towers and other machinery.

W11H series curve down bending machine The upper roller is fixed,two lower rollers do arc down movement around a fixed center of rotation,two bottom rollers can lift alone or in combination. Loading material for one time do not need to make a U-turn to complete pre-bending and adjust circle. Three work rolls are the main drive roller, and ensure that any thickness of material with good feeding coiled. Three rollers are close,able to roll small tube diameter and roundness correction. Features 1. Easy to operate, coiling method diversification. 2. The movement is simple (horizontal and vertical movement of the synthesis of movement, arc lifting movement), fault less. 3.Plate rolling process, always in a clamped state from sliding deviation. 4.Three working rollers diameter are the same.= 5.The workpiece can be removed under working rollers loosening clearance at any state no need to vertex position. 6 Microcomputer control, synchronization accuracy is ± 0.2mm.