PRODUCTS

As one new product of independent design & development, XH7126 is a multi-purpose machine which could mill surface & drill holes. This machine adopts domestic/overseas branded numerical control system and realizes full-screen edition in Chinese. Spindle adopts imported frequency converters, which could fulfill variable speed control & constant linear speed cutting functions; machining body adopts ultrasonic frequency hardening treatment; both X-axle & Z-axle adopts step/servo motor, which could process feeding motion by directly connecting shaft coupling & ball screws. With high power, pleasant rigidity, high precision & storage, high price-quality ratio and long cycle life, the machine is widely applied to instruments, meters, light industries, electronics, home appliances, medical instruments, aeronautics & astronautics and etc. industries, it is one small-medium precision & complex machine for processing various materials (especially non-ferrous metals & stainless steel) as well as an ideal equipments for large automation production. This machine could process holes below ∮16, milling plane below 18 and milling depth below 3mm.

As one new product of independent design & development, X7130 is a multi-purpose machine which could mill surface & drill holes. This machine adopts domestic/overseas branded numerical control system and realizes full-screen edition in Chinese. Spindle adopts imported frequency converters, which could fulfill variable speed control & constant linear speed cutting functions; machining body adopts ultrasonic frequency hardening treatment; both X-axle & Z-axle adopts step/servo motor, which could process feeding motion by directly connecting shaft coupling & ball screws. With high power, pleasant rigidity, high precision & storage, high price-quality ratio and long cycle life, the machine is widely applied to instruments, meters, light industries, electronics, home appliances, medical instruments, aeronautics & astronautics and etc. industries, it is one small-medium precision & complex machine for processing various materials (especially non-ferrous metals & stainless steel) as well as an ideal equipments for large automation production. This machine could process holes below ∮16, milling plane below 18 and milling depth below 3mm.

As one new product of independent design & development, XH7136 is a multi-purpose machine which could mill surface & drill holes. This machine adopts domestic/overseas branded numerical control system and realizes full-screen edition in Chinese. Spindle adopts imported frequency converters, which could fulfill variable speed control & constant linear speed cutting functions; machining body adopts ultrasonic frequency hardening treatment; both X-axle & Z-axle adopts step/servo motor, which could process feeding motion by directly connecting shaft coupling & ball screws. With high power, pleasant rigidity, high precision & storage, high price-quality ratio and long cycle life, the machine is widely applied to instruments, meters, light industries, electronics, home appliances, medical instruments, aeronautics & astronautics and etc. industries, it is one small-medium precision & complex machine for processing various materials (especially non-ferrous metals & stainless steel) as well as an ideal equipments for large automation production. This machine could process holes below ∮16, milling plane below 18 and milling depth below 3mm.

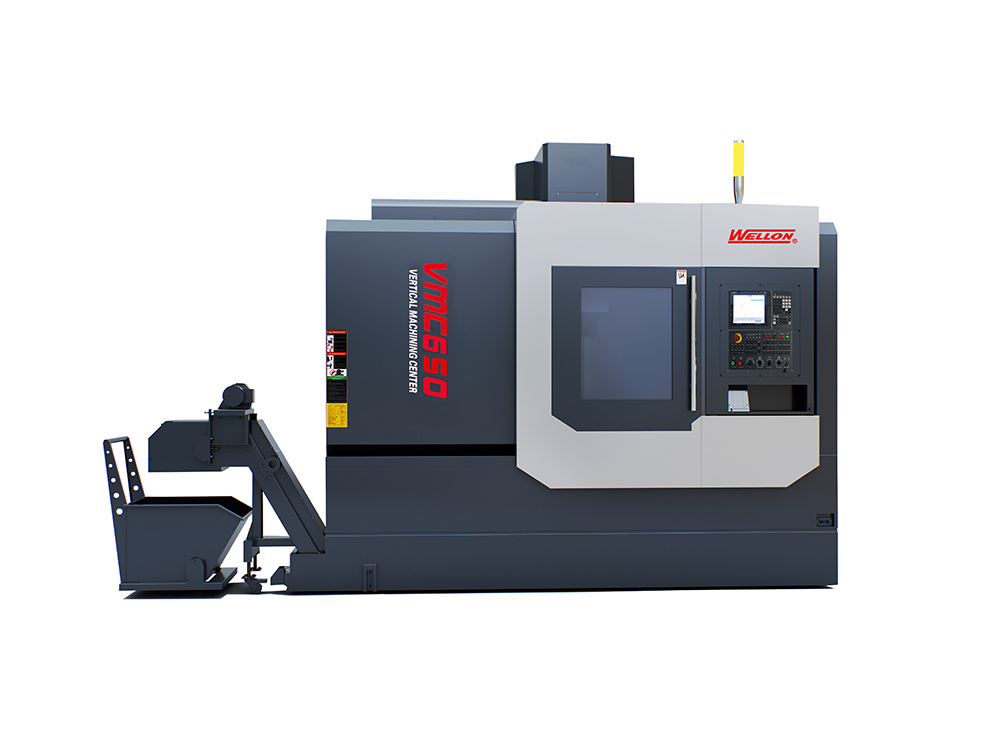

Main configuration & accessories: 1. Resin sand casting, Meehanite HT-300; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Roller type linear guideway from Taiwan 5. Ball lead screw from Taiwan 6. Standard with belt driven spindle, optional for direct driven spindle; 7. Taiwan pneumatic cylinder; 8. Taiwan ATC, umbrella type and disc type both are available; 9. Import bearings for leadsrews; 10. Import coupling; 11. Headstock Nitrogen balance system as optional; 12. Full enclosed cover; 13. Rigid tapping; 14. Spindle center ring blast; 15. Work lamp; 16. Pilot lamp; 17. USB interface; 18. Manual pulse generator (MPG); 19. Centralized automatic lubrication system. 20. Cooling system. 21. Heat exchanger for electrical cabinet ; 22. Leveling blocks & bolts; 23. Air gun+water gun;

Main configuration & accessories: 1. Resin sand casting, Meehanite HT-300; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Roller type linear guideway from Taiwan 5. Ball lead screw from Taiwan 6. Standard with belt driven spindle, optional for direct driven spindle; 7. Taiwan pneumatic cylinder; 8. Taiwan ATC, umbrella type and disc type both are available; 9. Import bearings for leadsrews; 10. Import coupling; 11. Headstock Nitrogen balance system as optional; 12. Full enclosed cover; 13. Rigid tapping; 14. Spindle center ring blast; 15. Work lamp; 16. Pilot lamp; 17. USB interface; 18. Manual pulse generator (MPG); 19. Centralized automatic lubrication system. 20. Cooling system. 21. Heat exchanger for electrical cabinet ; 22. Leveling blocks & bolts; 23. Air gun+water gun;

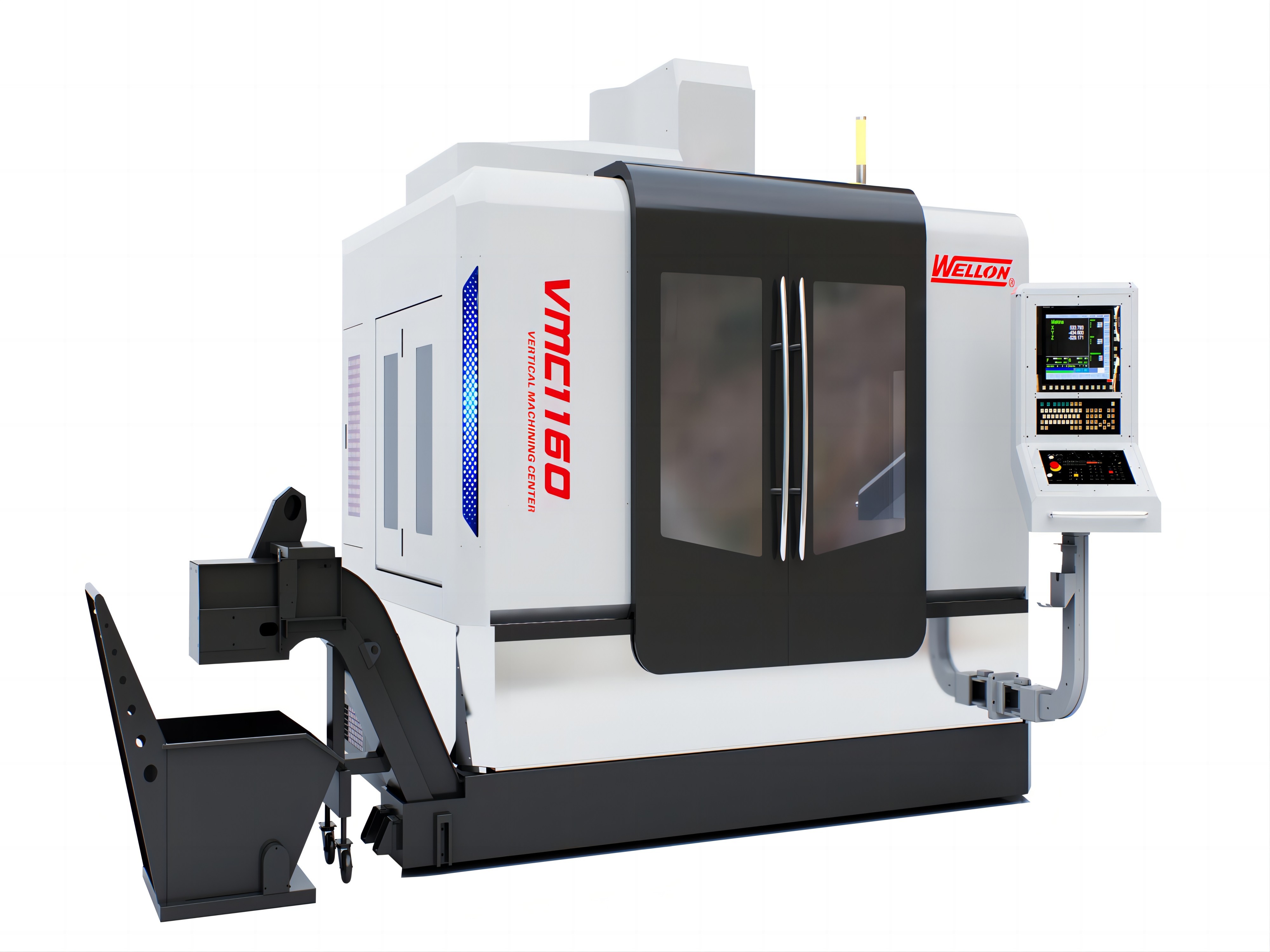

Main configuration & accessories: 1. Resin sand casting; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Standard with belt driven spindle, optional for direct driven spindle; 5. Taiwan production pneumatic cylinder; 6. Taiwan ATC, umbrella type and disc type are available; 7. Import bearings for leadsrews; 8. Import coupling; 9. Headstock balancing system have heavy casting or nitrogen balance system as option; 10. Full enclosed cover; 11. Rigid tapping; 12. Spindle center air blast; 13. Work lamp; 14. Pilot lamp; 15. USB and Internet interface; 16. Manual pulse generator (MPG); 17. Centralized automatic lubrication system. 18. Cooling system. 19. Heat exchanger for electrical cabinet ; 20. Leveling blocks & bolts; 21. Toolbox and tools; 22. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, etc.

Main configuration & accessories: 1. Resin sand casting; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Standard with belt driven spindle, optional for direct driven spindle; 5. Taiwan production pneumatic cylinder; 6. Taiwan ATC, umbrella type and disc type are available; 7. Import bearings for leadsrews; 8. Import coupling; 9. Headstock balancing system have heavy casting or nitrogen balance system as option; 10. Full enclosed cover; 11. Rigid tapping; 12. Spindle center air blast; 13. Work lamp; 14. Pilot lamp; 15. USB and Internet interface; 16. Manual pulse generator (MPG); 17. Centralized automatic lubrication system. 18. Cooling system. 19. Heat exchanger for electrical cabinet ; 20. Leveling blocks & bolts; 21. Toolbox and tools; 22. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, etc.

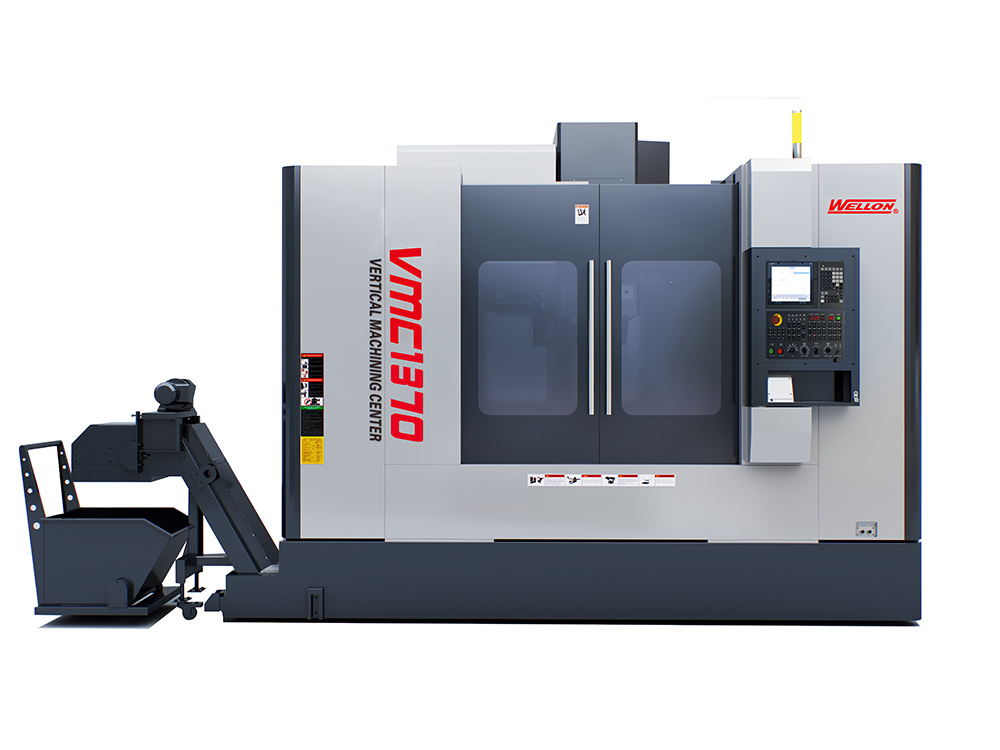

Main configuration & accessories: 1. Resin sand casting; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Standard with belt driven spindle, optional for direct driven spindle; 5. Taiwan production pneumatic cylinder; 6. Taiwan ATC, umbrella type and disc type are available; 7. Import bearings for leadsrews; 8. Import coupling; 9. Headstock balancing system have heavy casting or nitrogen balance system as option; 10. Full enclosed cover; 11. Rigid tapping; 12. Spindle center air blast; 13. Work lamp; 14. Pilot lamp; 15. USB and Internet interface; 16. Manual pulse generator (MPG); 17. Centralized automatic lubrication system. 18. Cooling system. 19. Heat exchanger for electrical cabinet ; 20. Leveling blocks & bolts; 21. Toolbox and tools; 22. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, etc.

Main configuration & accessories: 1. Resin sand casting; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Standard with belt driven spindle, optional for direct driven spindle; 5. Taiwan production pneumatic cylinder; 6. Taiwan ATC, umbrella type and disc type are available; 7. Import bearings for leadsrews; 8. Import coupling; 9. Headstock balancing system have heavy casting or nitrogen balance system as option; 10. Full enclosed cover; 11. Rigid tapping; 12. Spindle center air blast; 13. Work lamp; 14. Pilot lamp; 15. USB and Internet interface; 16. Manual pulse generator (MPG); 17. Centralized automatic lubrication system. 18. Cooling system. 19. Heat exchanger for electrical cabinet ; 20. Leveling blocks & bolts; 21. Toolbox and tools; 22. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, etc.

1. Resin sand casting; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Standard with belt driven spindle, optional for direct driven spindle; 5. Taiwan production pneumatic cylinder; 6. Taiwan ATC, umbrella type and disc type are available; 7. Import bearings for leadsrews; 8. Import coupling; 9. Headstock balancing system have heavy casting or nitrogen balance system as option; 10. Full enclosed cover; 11. Rigid tapping; 12. Spindle center air blast; 13. Work lamp; 14. Pilot lamp; 15. USB and Internet interface; 16. Manual pulse generator (MPG); 17. Centralized automatic lubrication system. 18. Cooling system. 19. Heat exchanger for electrical cabinet ; 20. Leveling blocks & bolts; 21. Toolbox and tools; 22. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, et

Main configuration & accessories: 1. Resin sand casting; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Standard with belt driven spindle, optional for direct driven spindle; 5. Taiwan production pneumatic cylinder; 6. Taiwan ATC, umbrella type and disc type are available; 7. Import bearings for leadsrews; 8. Import coupling; 9. Headstock balancing system have heavy casting or nitrogen balance system as option; 10. Full enclosed cover; 11. Rigid tapping; 12. Spindle center air blast; 13. Work lamp; 14. Pilot lamp; 15. USB and Internet interface; 16. Manual pulse generator (MPG); 17. Centralized automatic lubrication system. 18. Cooling system. 19. Heat exchanger for electrical cabinet ; 20. Leveling blocks & bolts; 21. Toolbox and tools; 22. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, etc.

Main configuration & accessories: 1. Resin sand casting; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Standard with belt driven spindle, optional for direct driven spindle; 5. Taiwan production pneumatic cylinder; 6. Taiwan ATC, umbrella type and disc type are available; 7. Import bearings for leadsrews; 8. Import coupling; 9. Headstock balancing system have heavy casting or nitrogen balance system as option; 10. Full enclosed cover; 11. Rigid tapping; 12. Spindle center air blast; 13. Work lamp; 14. Pilot lamp; 15. USB and Internet interface; 16. Manual pulse generator (MPG); 17. Centralized automatic lubrication system. 18. Cooling system. 19. Heat exchanger for electrical cabinet ; 20. Leveling blocks & bolts; 21. Toolbox and tools; 22. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, etc.