CMC170U

Classification:

keyword:

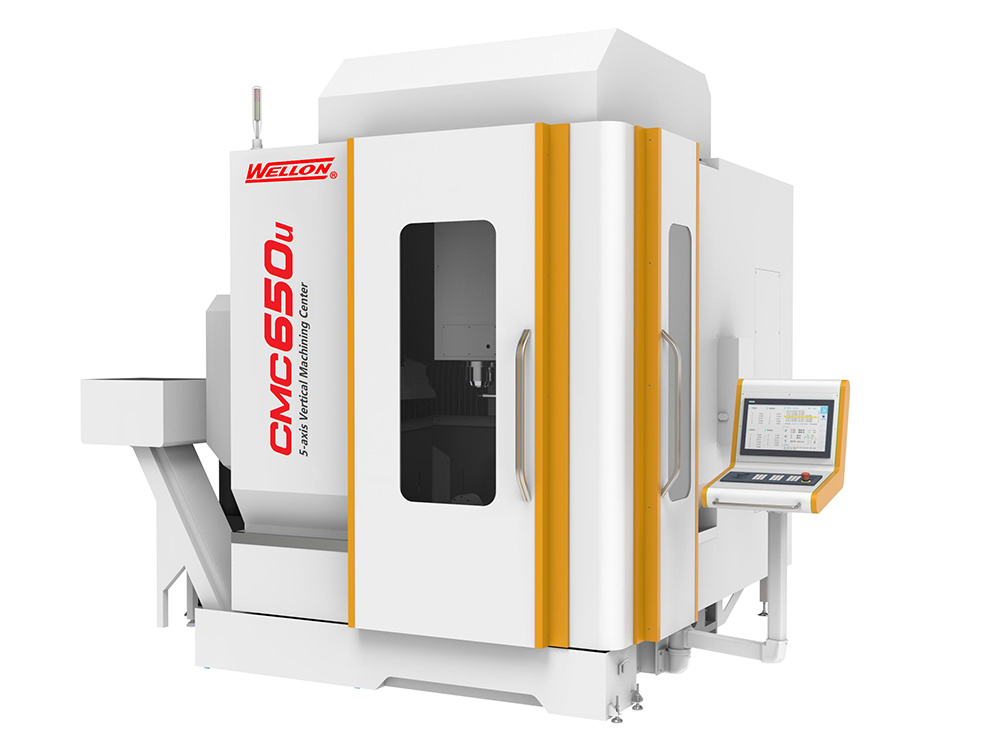

5 axis Machining Center

WhatsApp:+86-13969473068

- Details

- Standard accessories

- Optional accessories

-

- 商品名称: CMC170U

The CMC series five-sided machining center is mainly used for batch processing of box parts, shell parts, molds and other parts with high precision, multiple procedures, and complex shapes. It can continuously complete milling, drilling, expanding, reaming, and boring in one clamping. Tapping and precise processing of three-dimensional curved surfaces and inclined surfaces. The processing is programmed and batched, which shortens the production cycle and enables users to obtain good economic benefits. This series of models is an ideal and cost-effective 5-sided machining center.

Item

Unit

WMC170A

Table size

mm

Φ200

Left and right travel(X)

mm

600

Front and back travel(Y)

mm

200

Up and down travel(Z)

mm

300

B/C travel

Spindle nose to worktable

mm

80-380

Spindle center to column guideway

mm

140

5 axis rotary table brand

TB-YL-200

T-slots(NO./width/pitch)

4-12x90°

Spindle taper

BT30-100 direct driven

Spindle speed

rpm

20000

Capacity

pcs

BT30-8T domestic servo tool magazine

X,Y,Z linear guideway size

Roller30

X,Y,Z ball leadscrew size

mm

3210/3210/3210

Max loading capacity

kg

50

X,Y,Z motor connection mode

Electrical direct

Main motor power

kw

3.7/5.5

Fast moving speed (X/Y/Z)

m/min

30/30/30

Feed motor torque

Nm

2016/12/16

Bed cushion height

mm

40

Inner and outer sheet metal

(including chain conveyor, chip bucket )Standard accessories

Net weight of optical machine

(without worktable)T

2.3

Notes:1.Our company is studying and reproving at any time, so we have the right to change the parameter at any moment. Please forgive us for changing it without informing you, thanks.

-

Siemens 840D SL controller

12000 rpm motor spindle taper SK40

Spindle oil cooler

24 Tools Magazine

3 Axis straight measuring systems (rulers), full closed loop system

Taiwan rotary table dritect driven type

X,Y,Z axis linear guideway from Taiwan

Chain type conveyor + Spiral type conveyor

Air conditioner in cabinet

Automatic door

Air gun + Water gun

Full closed cover

Working lamp and alarm lamp

Preparation for automation (Robot solutions)

-

Fanuc 0i-MF(5) controller

Siemens 828D controller

Mitsubishi M80A/B controler

32 Tools Magazine

30 bar Water through spindle center

Renishaw Probe measuring system OMP60 (infrared)

Renishaw Tool setting system TS-27R (infrared)

RELATED PRODUCTS

CONTACT US

No.766 Tongda road,Tengzhou city, Shandong, China

FEEDBACK